As they continue down the road of digital transformation, a plurality of manufacturers looking at both Manufacturing Execution System (MES) and Enterprise Resource Planning (ERP) systems aren’t trying to determine which technology they need—they’re invested in learning how these two offerings work together.

Whether you’re evaluating software for the first time or looking to better integrate your existing platforms, this guide explores the core functions of MES and ERP, and how these two versatile—and different—technologies work together to create a unified impact.

Table of Contents

MES vs. ERP: Comparison & Definitions

Now, let’s take a closer look at each system’s key benefits and use cases.

MES

Manufacturing Execution Systems monitor, track, document, and help teams execute and control production processes in real-time. These platforms bridge the gap between business-level planning and machine-level operations, helping establish enterprise-wide visibility, knowledge, and control.

Core MES Functions:

- Real-time data collection and monitoring

- Production scheduling, execution, and workflow management

- Resource allocation and tracking

- Performance and OEE analysis

- Quality management and defect tracking

- Maintenance and downtime management

- End-to-end traceability and audit trails

- Compliance and reporting

ERP

Enterprise Resource Planning systems streamline the management of core business functions by centralizing data and processes into one integrated platform. These systems unify departments and improve collaboration to drive higher productivity, uncover insights, and reduce risk.

Core ERP Functions:

- Project management

- Business intelligence and reporting

- Financial management

- Inventory order management

- Human resources and payroll

- Supply chain management

- Customer relationship management (CRM)

- Manufacturing (basic, high-level production planning)

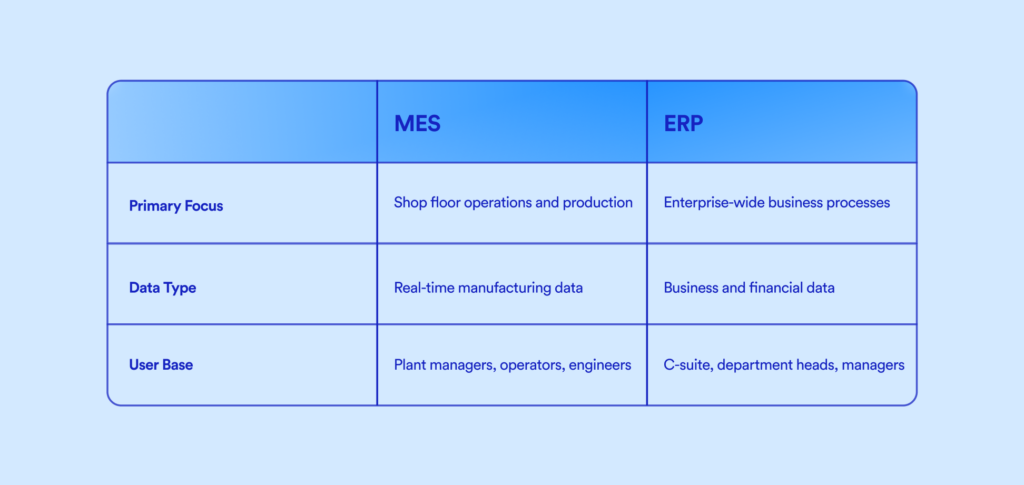

MES vs. ERP: Five Key Differences

-

Scope and Functionality

- MES offers deep visibility at the operational level by collecting, monitoring, and analyzing data from the shop floor.

- ERP systems take a broader view, integrating multiple departments and business functions into one system.

Data Collection and Processing

- MES collects real-time data from machines, sensors, and operators for live production monitoring.

- ERP systems glean insights from transactional business data such as orders, invoices, and financials, which are analyzed intermittently.

User Interface and Accessibility

- MES interfaces are optimized for production environments with intuitive, user-specific dashboards—think shop floor monitors, HMIs, and mobile devices.

- ERP systems are typically accessed by management and back-office teams through web and desktop portals.

Reporting and Analytics

- MES provides real-time reporting from high-level summaries to granular details—filter by categories such as shift, line, batch, product, operator, etc. Intelligence from these platforms enables teams to monitor operational KPIs such as OEE and Quality. They enable root-cause analysis and support Lean Manufacturing initiatives.

- ERP provides high-level business reports related to financial performance, inventory, and forecasting.

Scalability and Flexibility

- MES platforms can be modular and customizable to allow for phased implementation.

- ERP systems are scalable across business functions but may be less agile in adapting to specific shop floor changes without customization.

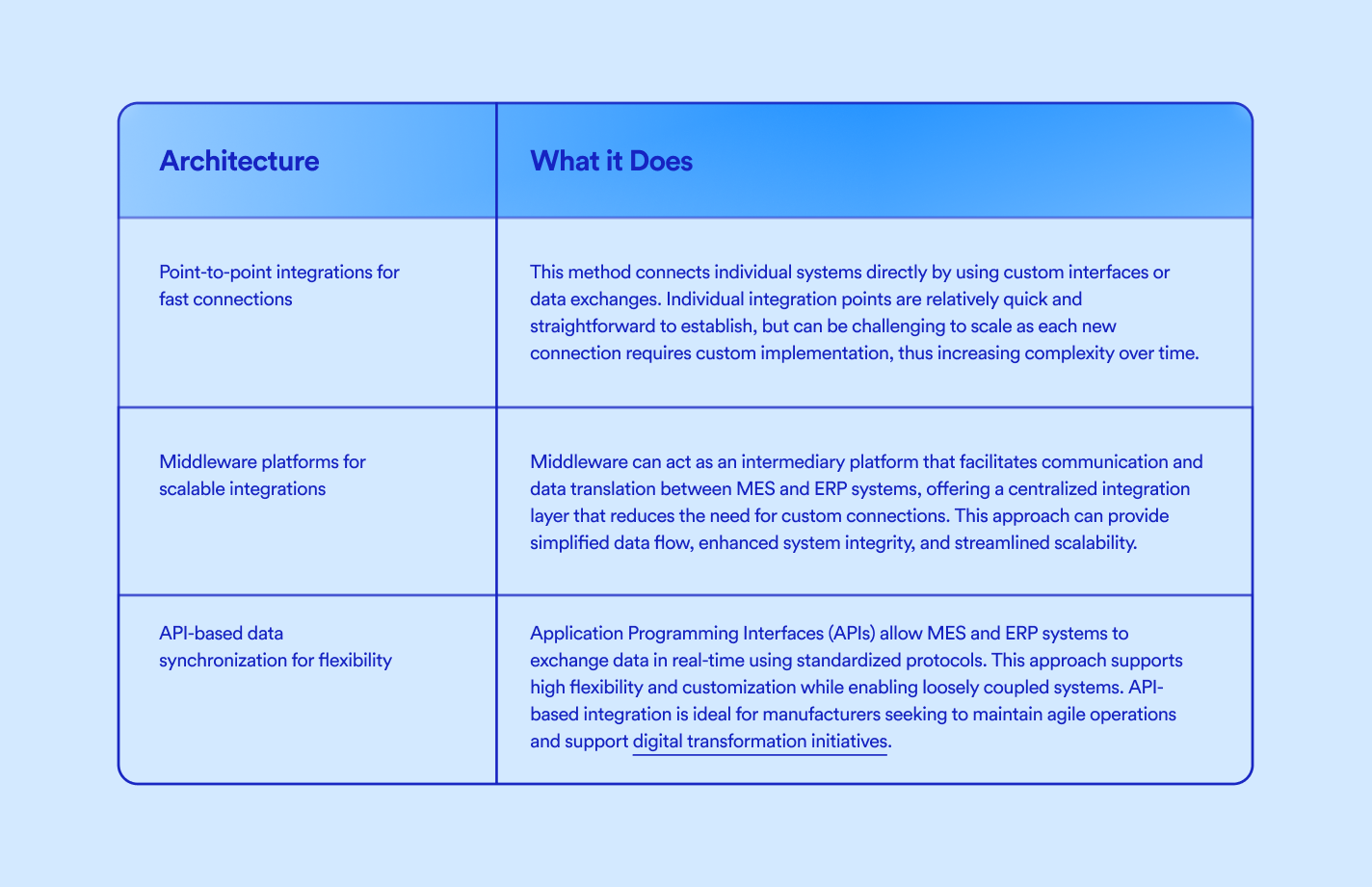

MES and ERP Integration Best Practices

ROI Analysis and Cost-Benefit Comparison

Conclusion

FAQ

Can ERP replace MES?

Do I need both MES and ERP?

What’s the difference between MES and SCADA?

SCADA (Supervisory Control and Data Acquisition) systems focus on monitoring and controlling physical processes at the machine and equipment level. MES builds on this by adding context, workflow management, and data analytics to orchestrate and optimize the entire production process. While SCADA tells you what’s happening at the machine level, MES tells you why it matters and how to improve it in the broader operational context.