Key Features

The Worlds’ Most Agile, Flexible, Extensible Manufacturing Operations Management Platform

With a library of configurable features that conform to the Manufacturing Operations Management (MOM) standard architecture, the TrakSYS software platform allows you to deploy manufacturing operations management solutions quickly and cost-effectively. Use the built-in features and functions of TrakSYS to build solutions for virtually any challenge — from OEE and SPC, to E-Records, Traceability, Workflow, and more.

Definitions

Resource Planning

Scheduling

Dispatch

Execution

Data Collection

Tracking

Analysis

One Platform. Many Solutions.

Use the TrakSYS MES platform to create solutions for real-time, data-driven manufacturing operations management. We have everything you need to succeed.

Inventory Management

Maintain tight control of inventory to increase production efficiency, and reduce working capital requirements.

Production Planning

Plan, schedule, execute, and deliver goods as efficiently and effectively as possible.

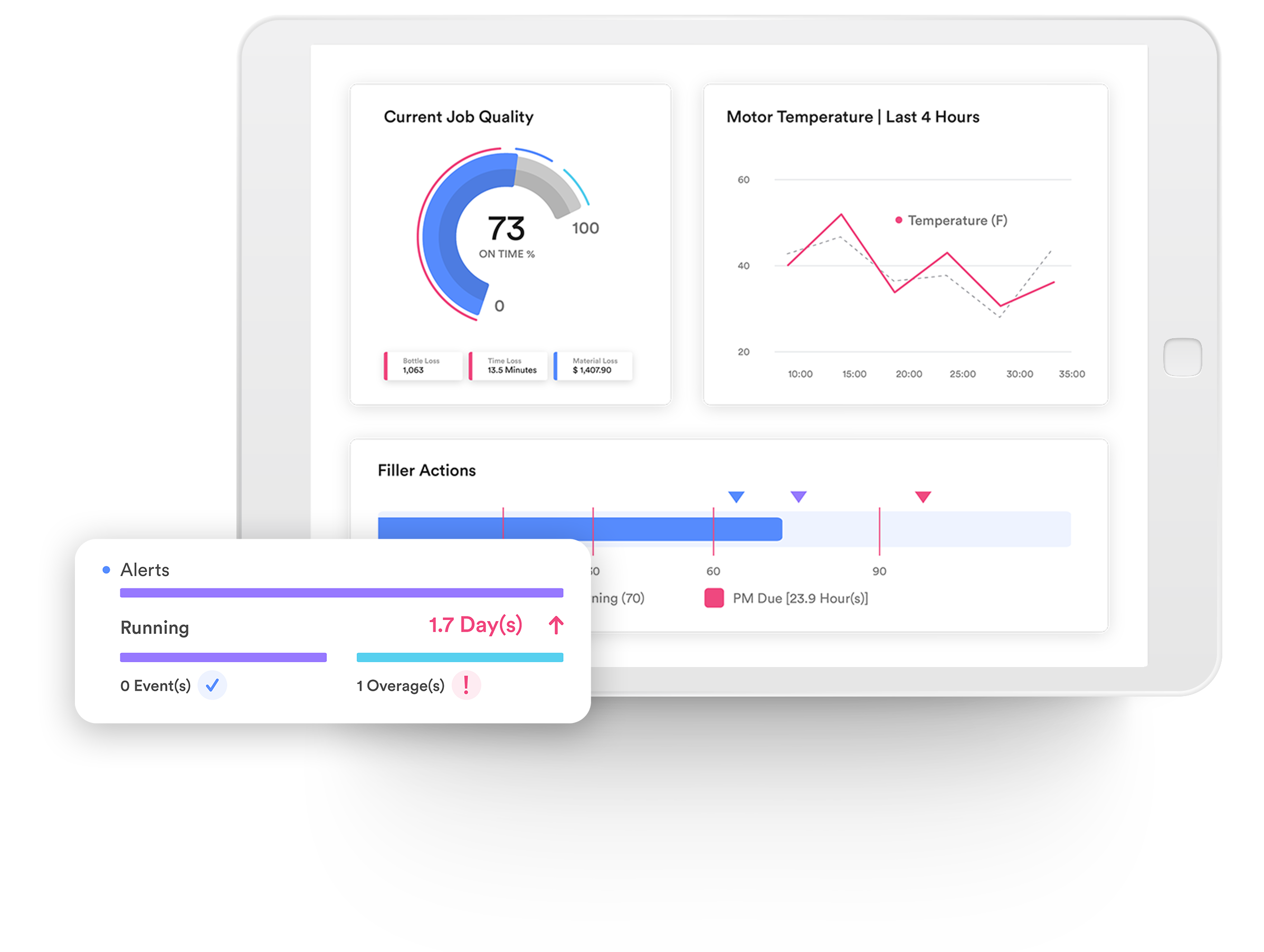

Quality Management

Gain real-time, insights into the causes of poor quality, and create a closed-loop system of statistical process control (SPC).

Predictive Maintenance

Boost equipment performance and analysis of real-time data gathered from machines, to help maximize overall productivity through predictive maintenance.

Key Features and Functions

TrakSYS is designed to be simple yet powerful, with features that help you get started quickly and grow as needed. Extensive out-of-the-box functionality ensures this. Whether your factory has one line or 100, and uses manual or automated production processes, TrakSYS provides a straightforward path to measurable improvement.

One Platform, Many Solutions

TrakSYS is a unified platform, with multiple, fully-integrated features to power business solutions.

Responsive Web Interface

TrakSYS utilizes the latest web platforms: HTML5, jQuery, Bootstrap, Backbone, SignalR, and more.

Single Sign-On

TrakSYS supports hybrid authentication, for users with or without a Windows/domain account.

Diverse Industries. Common Challenges.

The TrakSYS MES platform has been deployed at thousands of factories in over 100 countries, and in a variety of industries, including automotive, chemicals, food and beverage, life sciences, packaged goods, and more.

Thousands of Factories Worldwide Run More Productively with TrakSYS

Tony PetersonOperation Manager, Bush's Best

Stephen P. MonaghanP.E., Applied Control Engineering

Francisco JavierProduction Manager, Wyeth

Peter JanssenPlant IT Coordinator, Fermacell

Tim MillerQuality Manager, Hydranautics

Christophe JoubertProduction Manager, Messier Buggati

Craig MynattMES Project Lead, Proteus

Shane MorcomWorld-Class Champion, Royal Mail

Download the TrakSYS Brochure

Get the TrakSYS brochure. All the information you need for managing your manufacturing operations, in one convenient package.

We’re committed to your privacy. Parsec uses the information you provide to us to contact you about our relevant content, products, and services. You may unsubscribe from these communications at any time. For more information, check out our Privacy Policy.