Production Planning & Operations Management

Manufacturing Operations have many Inherent Complexities

Production and Operations Management with TrakSYS is designed to address those complexities so you can plan, schedule, execute, and deliver goods as efficiently and effectively as possible. As a purpose-built MOM platform, TrakSYS delivers interoperability to connect your business and manufacturing software systems involved in managing production planning, scheduling, and warehouse inventory management.

Optimize Planning & Scheduling

Increase On-Time Delivery

Improve Productivity

Improve Profitability

A Complete Production Management Solution

TrakSYS Real-Time Production Management solution integrates with ERP to carry out Advanced Planning and Scheduling, and route production information to systems, equipment, and people. Instead of isolated data within individual systems, with TrakSYS, it will become the force behind managing and executing manufacturing production activities in a cohesive, seamless, and repeatable manner.

Assign Job/Process Order

Synchronize with ERP or create jobs. Specify product quantities, schedule, asset assignments, and more. Quickly communicate production schedule revisions and priorities to the line and management level. Gain real-time visibility of job progress and schedule attainment.

Algorithmic Production Scheduling

Adjust your production schedule as events unfold. Real-time changes help ensure you meet production commitments by accounting for customer demand, warehouse inventory levels, asset capacity, historical output, commit dates, unexpected events (like equipment breakdowns), and more.

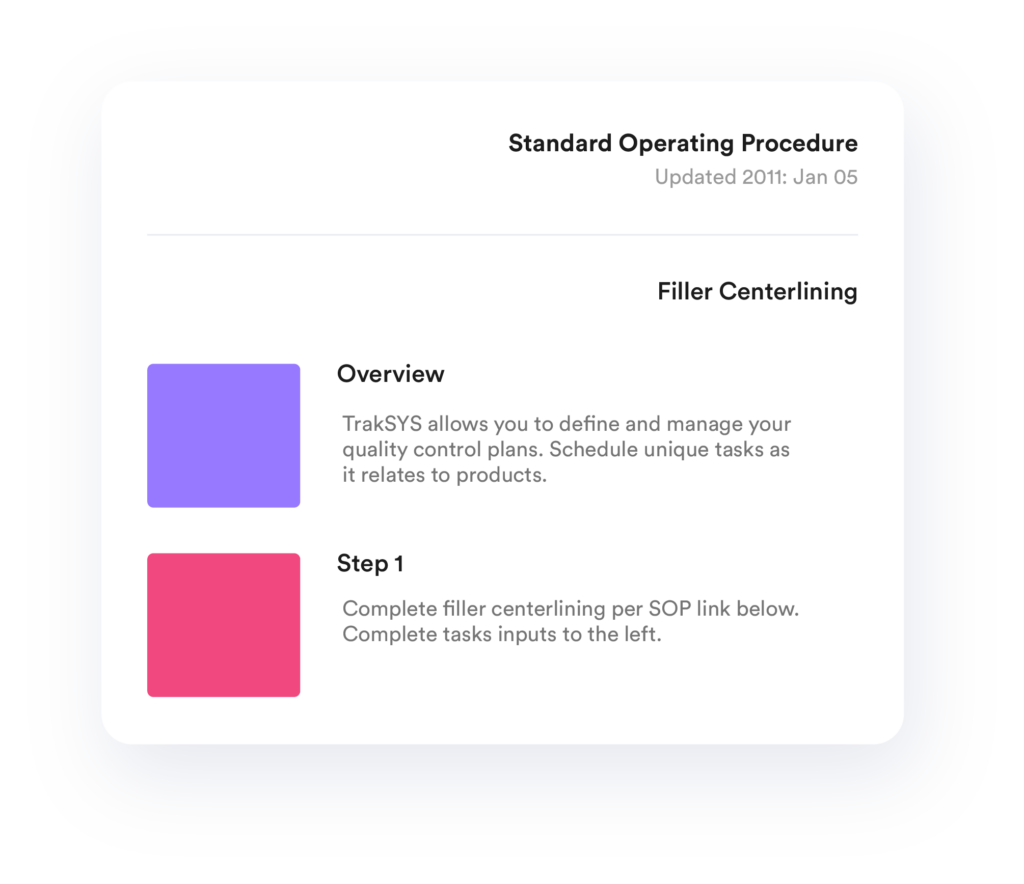

Reinforce Production Best Practices

Store documents in the built-in Document Library or link to externally stored files. Provide users quick access to standardize procedures in useful formats – pictures, videos, flowcharts, and checklists – reinforcing production best practices. TrakSYS Audit feature offers a configurable way to track documents and system revisions. Manage employee training, skill sets, certifications, authorization, and security clearance.

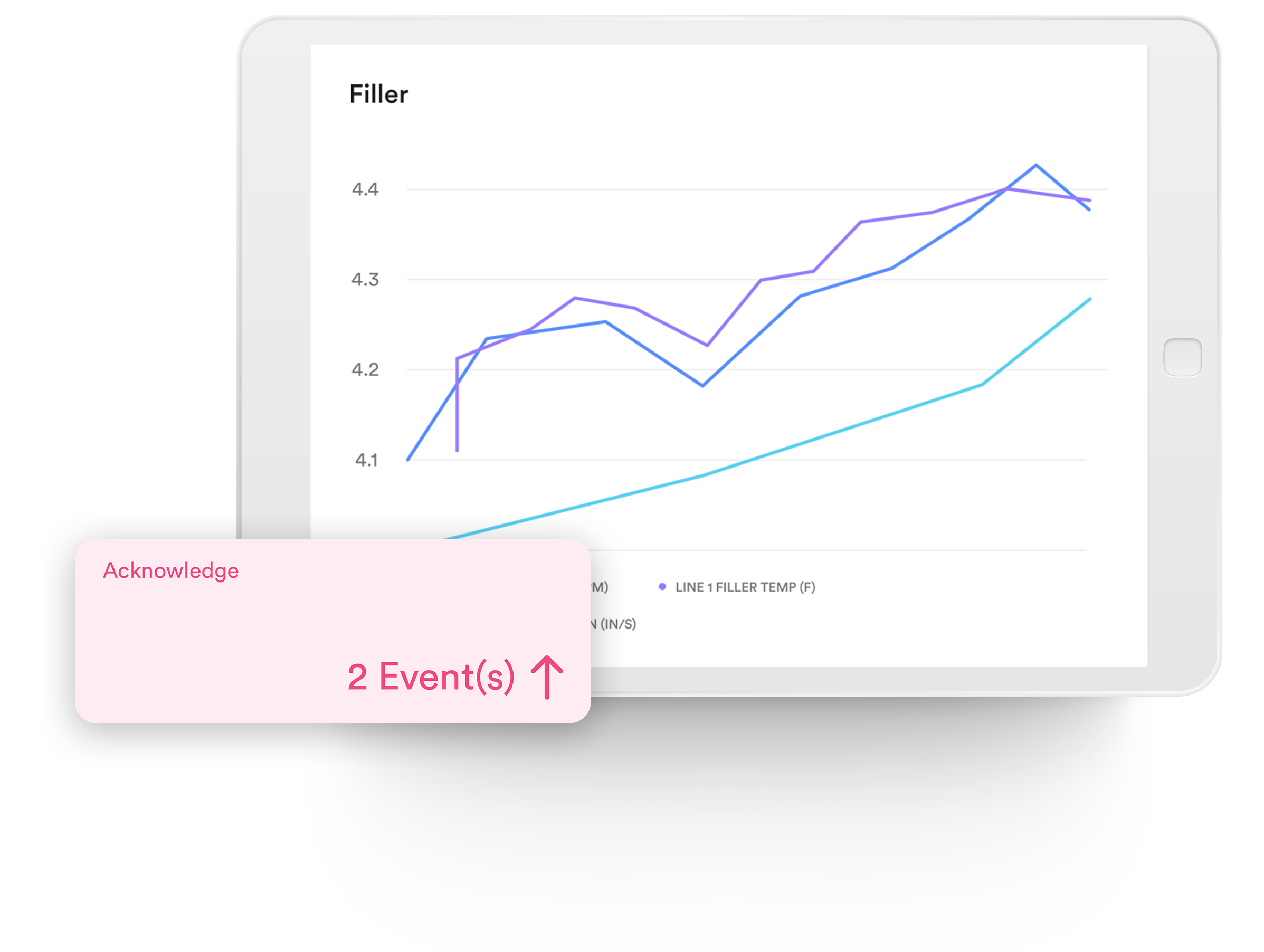

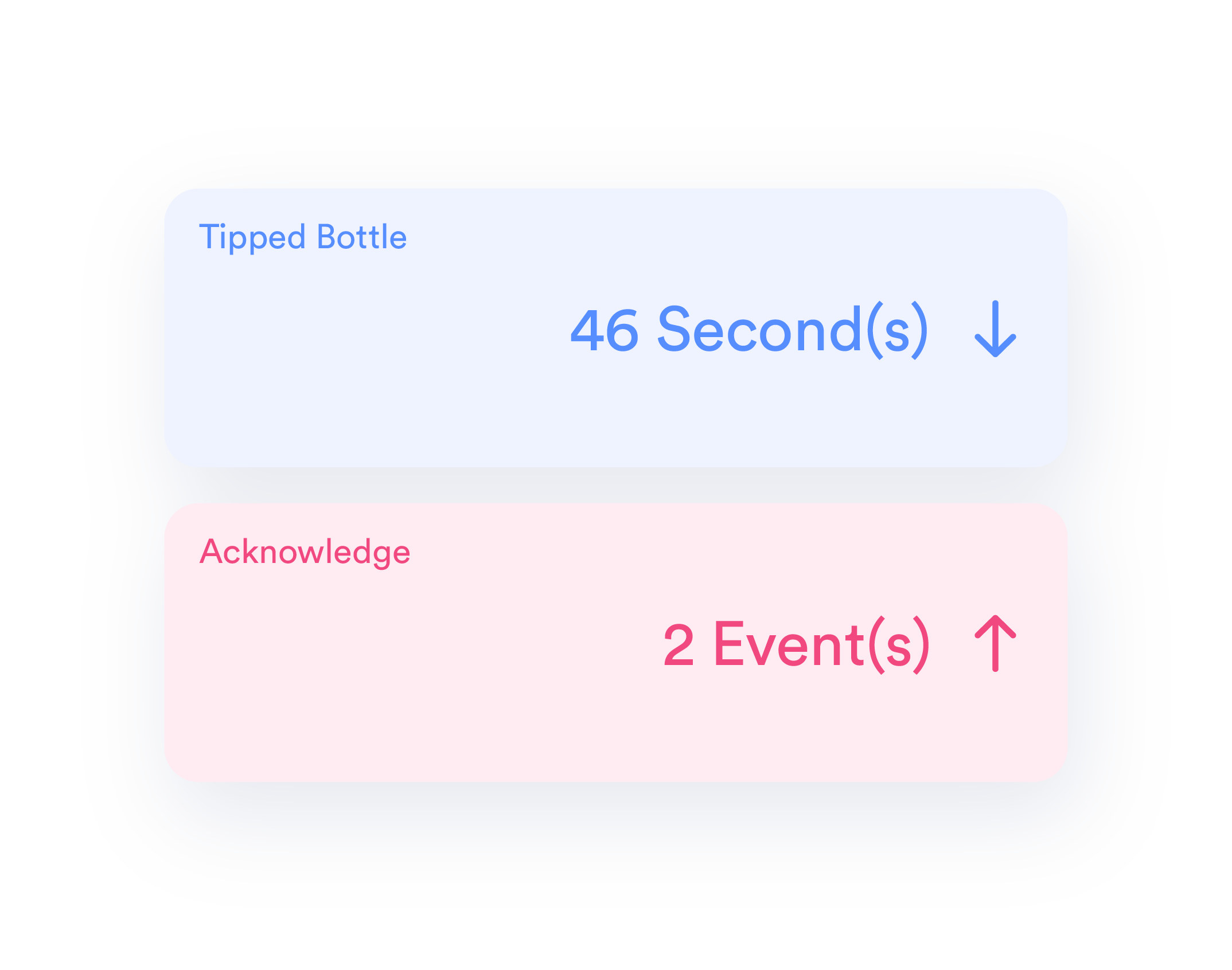

Track & Manage Events

Connected to your existing automation infrastructure, TrakSYS provides a clear view of what’s happening on your plant floor and informs you of events requiring attention. You can record a specific cause or even multiple causes of an event, and TrakSYS will analyze the trends.

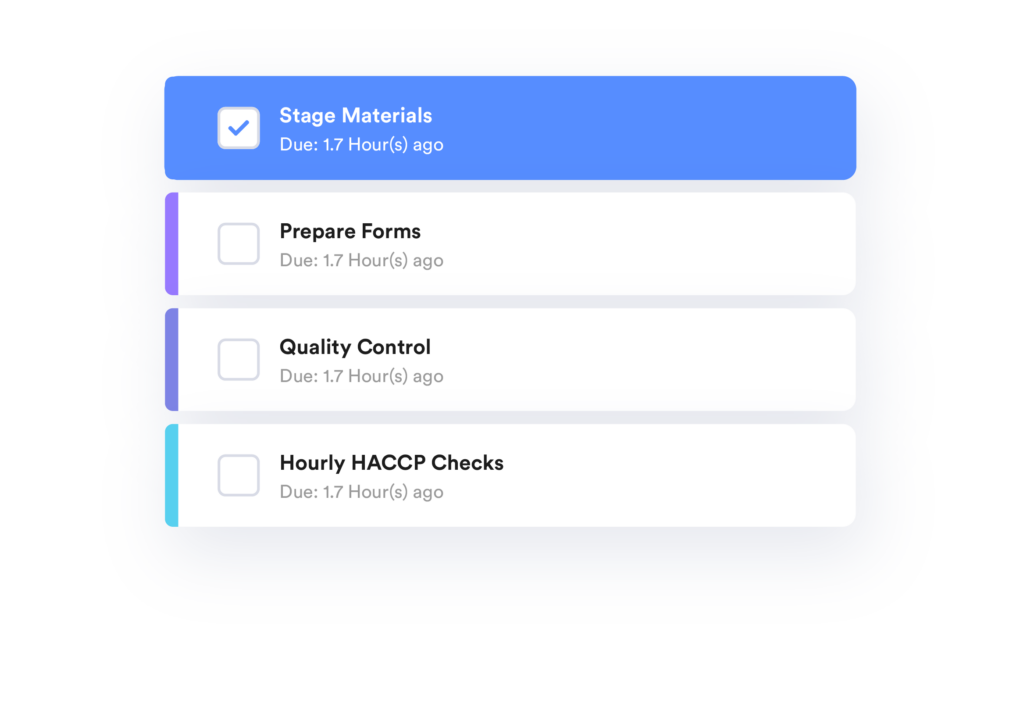

Tasks, Alerts, Journals & More

With real-time alerts, notifications, escalations, and the ability to configure automated workflows, TrakSYS gives you the tools to communicate and resolve production problems quickly and effectively.

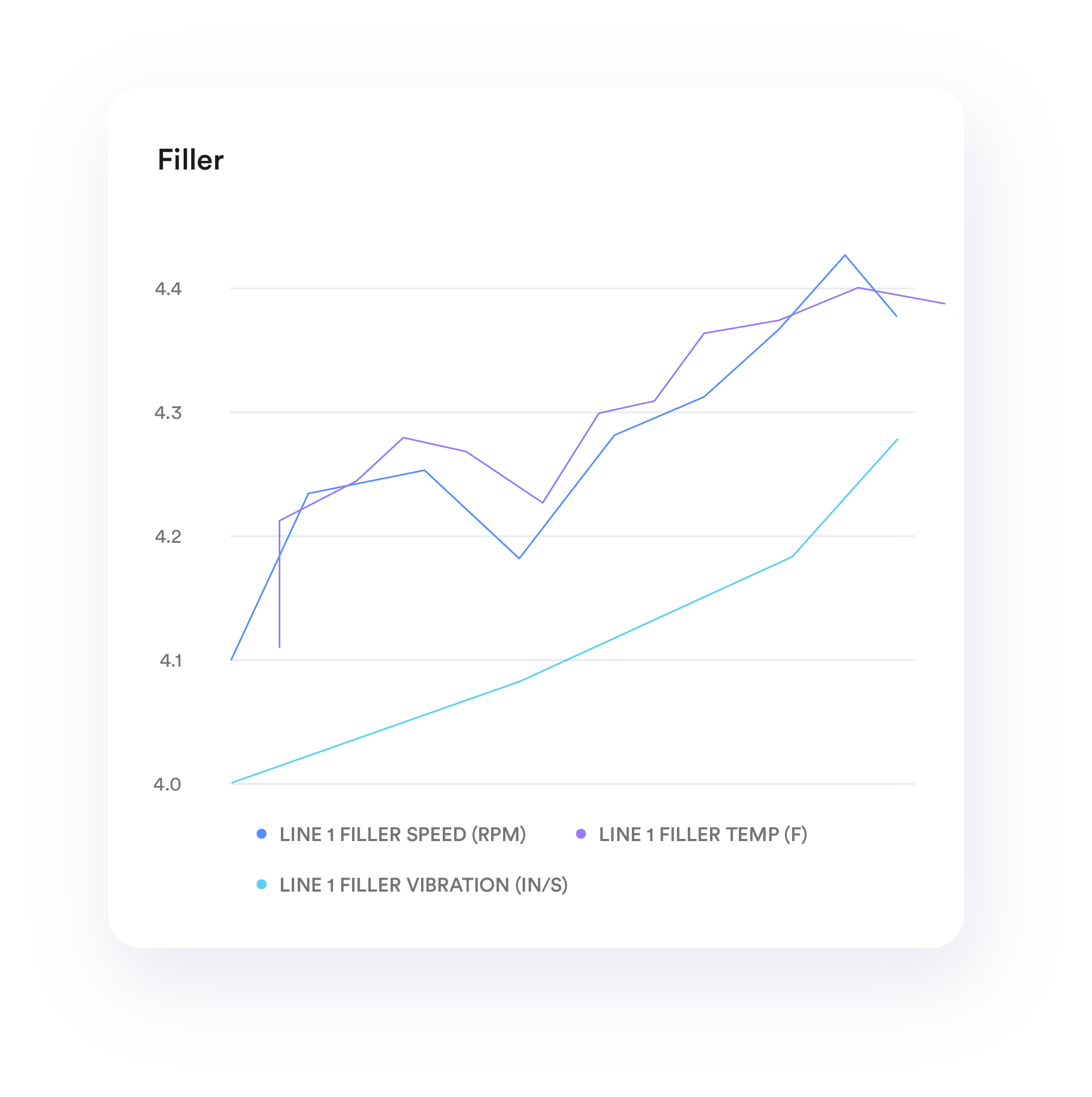

Data Historian

Connect to automation to record and retrieve time-series production and process data. Data Historian further enhances Traceability, enabling users to analyze sources of variation, identify process improvement opportunities, and quickly troubleshoot root causes.

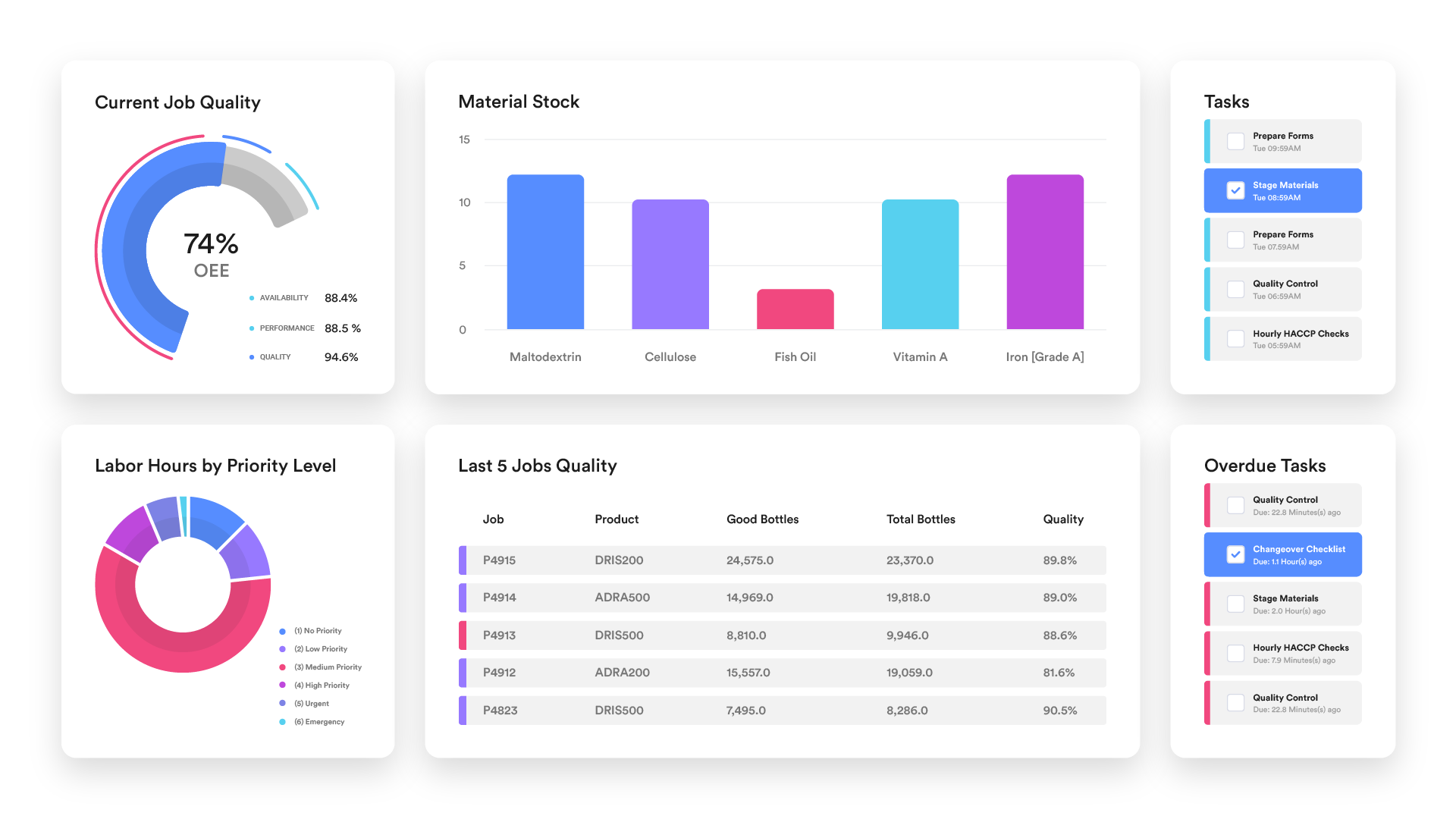

Metrics & Reporting

Gain visibility into production operations, including status of jobs, schedule attainment, and resource performance. Compare by operator, team, shift, route, supplier, lot and more to identify why “golden” runs are exceptional. Quickly determine areas of the factory that create production bottlenecks and prioritize your improvement plan.

Configurability

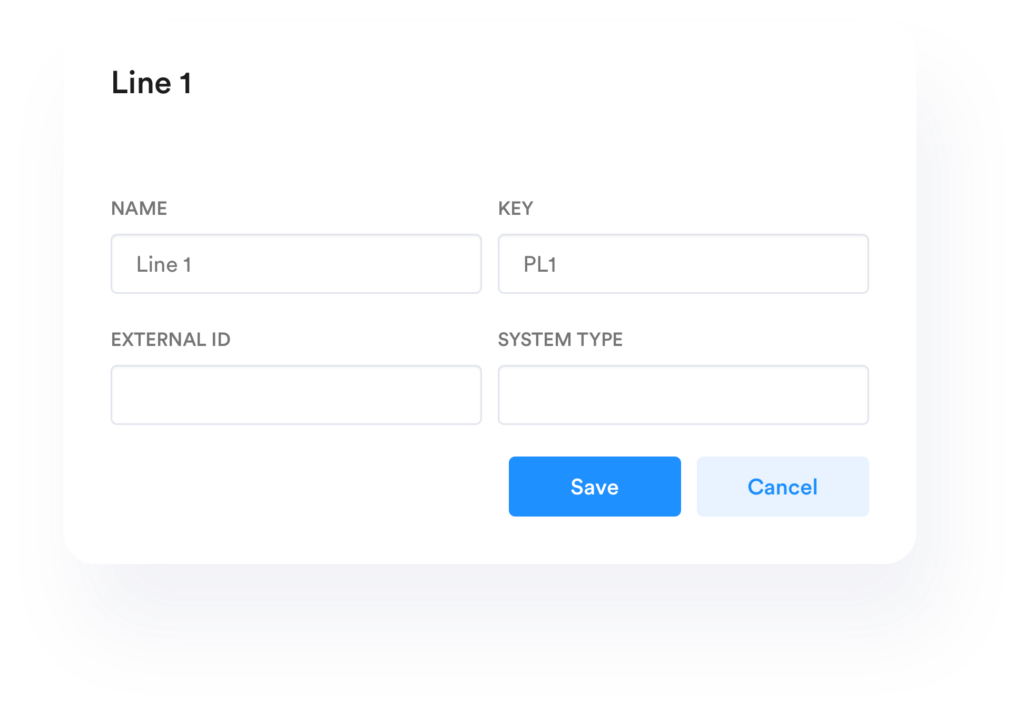

Web-based configuration tools and an integrated scripting environment allow the construction of tailored solutions without the need for custom code.

Extensibility

TrakSYS is a full MOM platform, with standard function libraries that can be readily adjusted to create focused solutions in a fraction of the time compared to traditional development. This important functionality delivers both rapid deployment and cost-effective extensibility.

Download The APS Brochure

Get the APS brochure. All the information you need, in one convenient package.

We’re committed to your privacy. Parsec uses the information you provide to us to contact you about our relevant content, products, and services. You may unsubscribe from these communications at any time. For more information, check out our Privacy Policy.