TrakSYS for Consumer Packaged Goods

A Bundle of Optimization

Consumer Packaged Goods (CPG) Manufacturing Software Trusted by Leading Manufacturers Worldwide

TrakSYS MES software has been deployed at thousands of factories in over 100 countries, including many leading consumer packaged goods manufacturers.

Unpack Real-Time Operations Data for Greater Productivity

As a consumer packaged goods (CPG) manufacturer your customers are more demanding than ever. They want top-quality products at competitive prices. And, of course, quality cannot be sacrificed in the name of speed and efficiency. How do you optimize operations, to balance these competing concerns? You need insights driven by real-time production data and tools to take action on those insights. TrakSYS can help.

Improve Quality

Reduce Downtime

Ensure Safety

Reduce Cost

How TrakSYS Helps You Gain Greater Visibility, Knowledge, and Control

TrakSYS helps packaged goods manufacturers enable operational excellence initiatives, meet safety compliance requirements, and support sustainability efforts. Here’s how:

Increased Productivity

Increase productivity through measurement such as OEE and TEEP, and automated corrective and preventive action using tasks and journals.

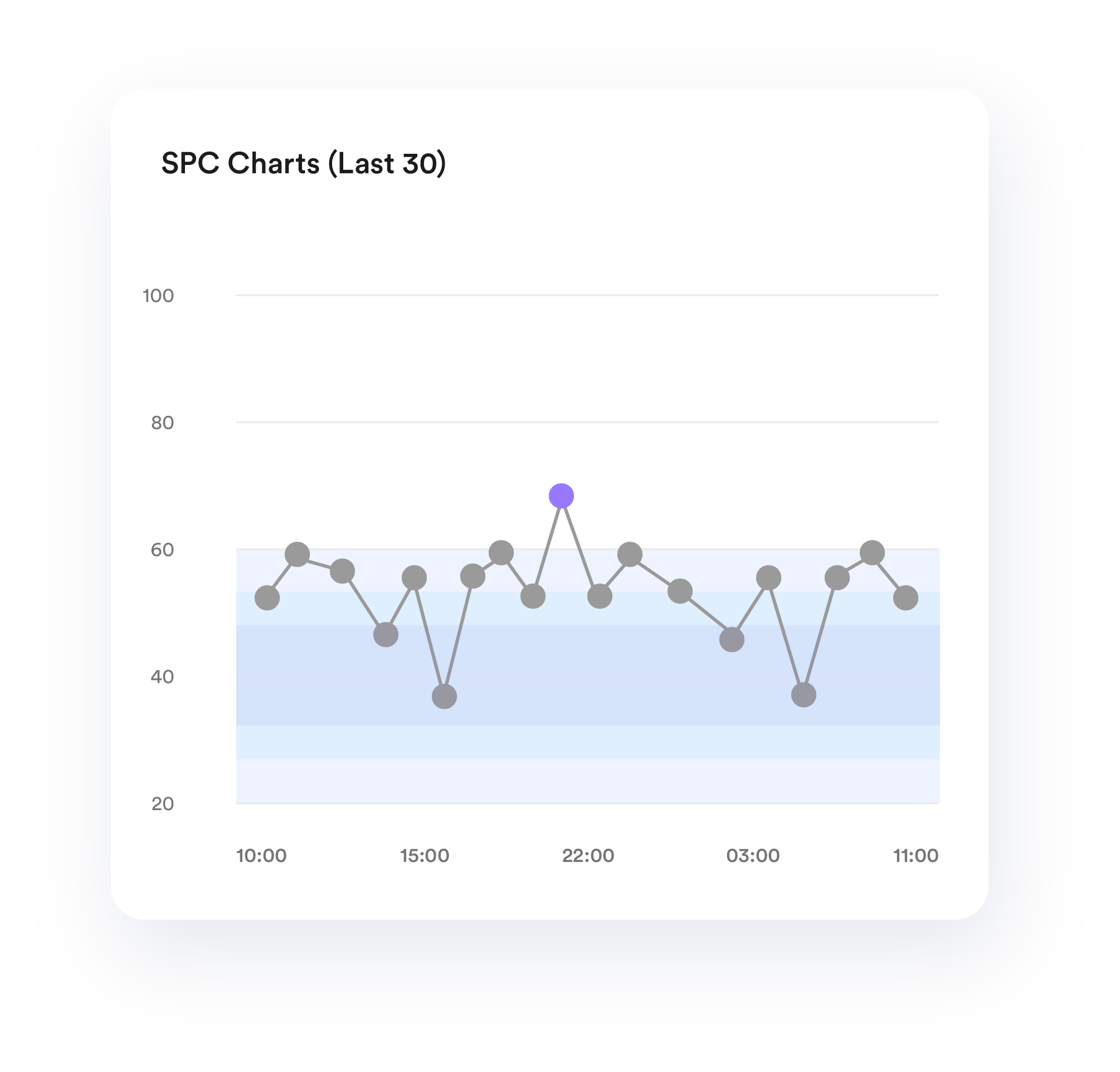

Quality Assurance

Enhance brand reputation and ensure FDA compliance with full ingredient and material traceability, including sourcing and supplier information.

Electronic Records

Automate your record-keeping, including changes, actions, recorded values, and electronic signatures, for the creation of a comprehensive audit trail.

Ensure consistency, quality, and replicability with a tamper-proof record of what ingredients (and what amounts) went into each batch of products.

Preventive and Predictive Maintenance

Coordinate preventive maintenance activities with production schedules. Tap into machine data and perform predictive maintenance to avoid unscheduled downtime.

Consumer Packaged Goods Related Content

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.