Predictive Maintenance Software

Manage Equipment Reliability and Longevity by being Proactive

The TrakSYS maintenance management solution provides insight into production processes, equipment performance, and analysis of real-time data gathered from machines, helping manufacturers maximize overall productivity through preventive and predictive maintenance management systems.

Maximize Capacity Utilization

Increase On-Time Delivery

Reduce Maintenance Costs

Extend Equipment Life

Download the Maintenance Management Brochure

We’re committed to your privacy. Parsec uses the information you provide to us to contact you about our relevant content, products, and services. You may unsubscribe from these communications at any time. For more information, check out our Privacy Policy.

More Flexible and Responsive Maintenance Management

Whether you now use a CMMS system, spreadsheets, or just pen and paper, adding TrakSYS will help improve the effectiveness of your predictive and preventive maintenance program. Based on an easy-to-use mobile software platform, TrakSYS works alongside your maintenance crew, providing greater visibility, knowledge, and control.

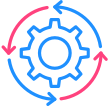

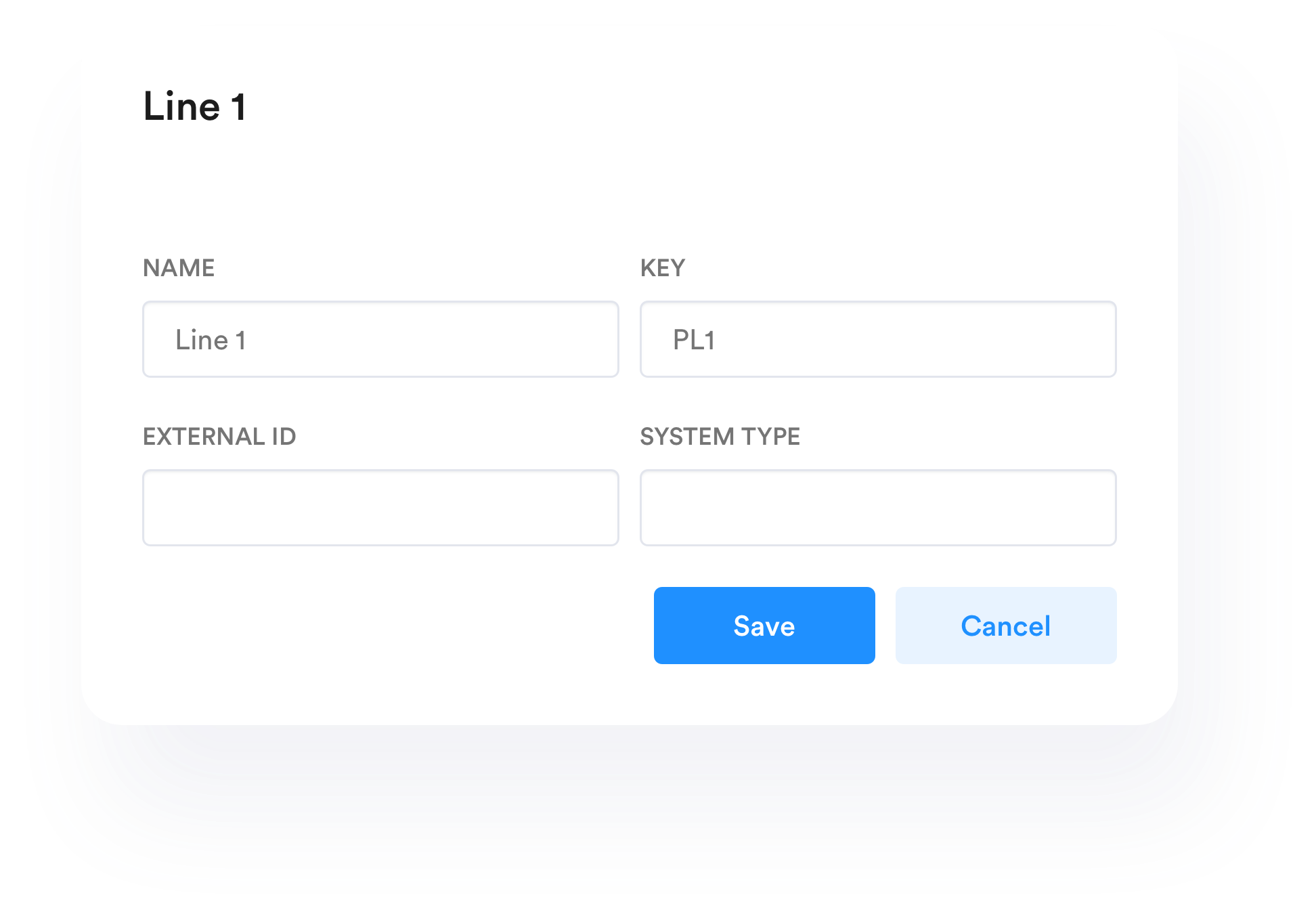

Work Order Management

Communicate work requests and prioritization to the maintenance department. Maintain records of work completed, labor utilized, and material cost.

Preventive Maintenance

Schedule equipment inspection and care using equipment runtime or cycles, monitored equipment conditions, or traditional time intervals.

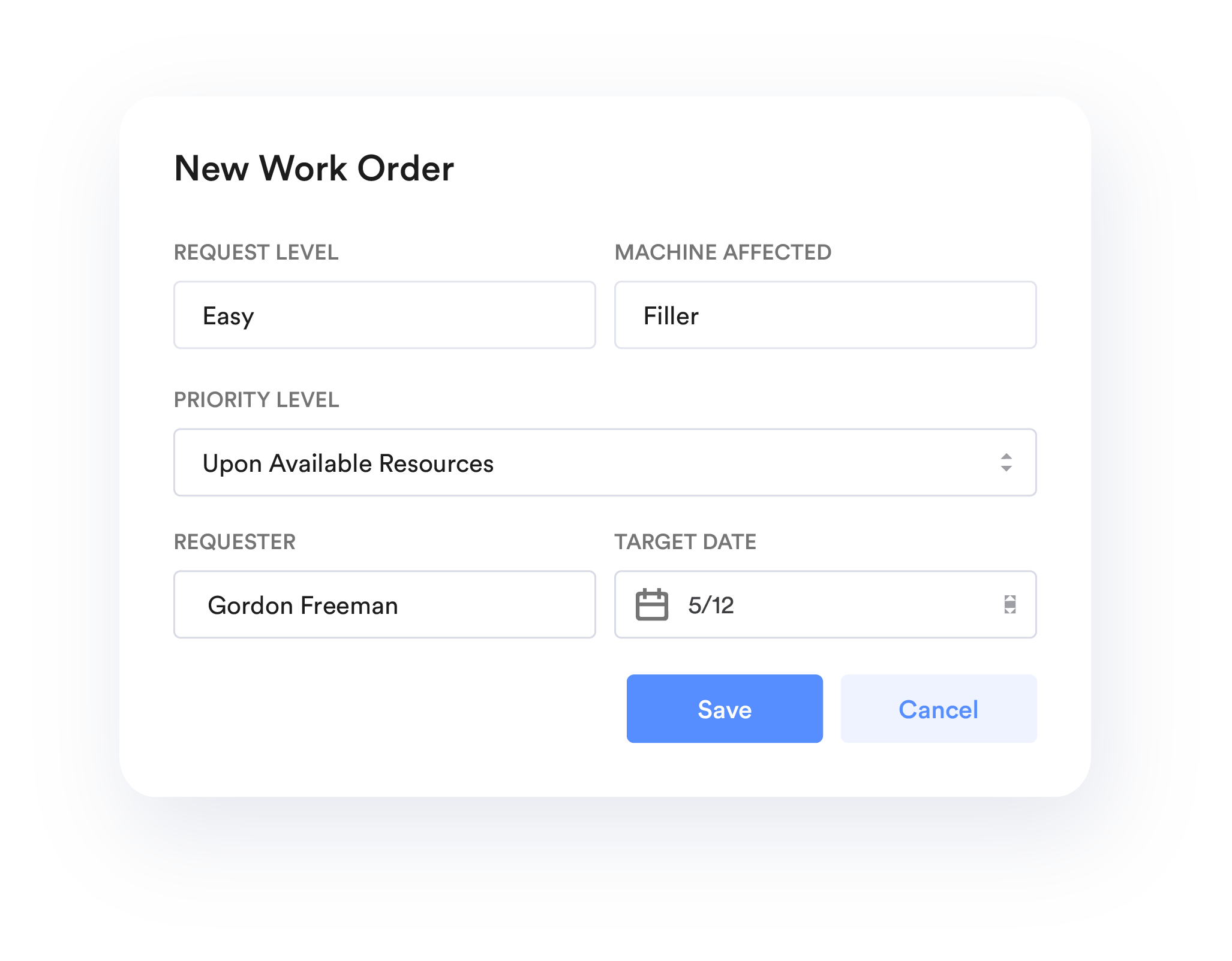

In-Line Work Instructions, Manuals, Locations

Provide maintenance technicians work instructions, equipment manuals, and spare part locations for quick reference.

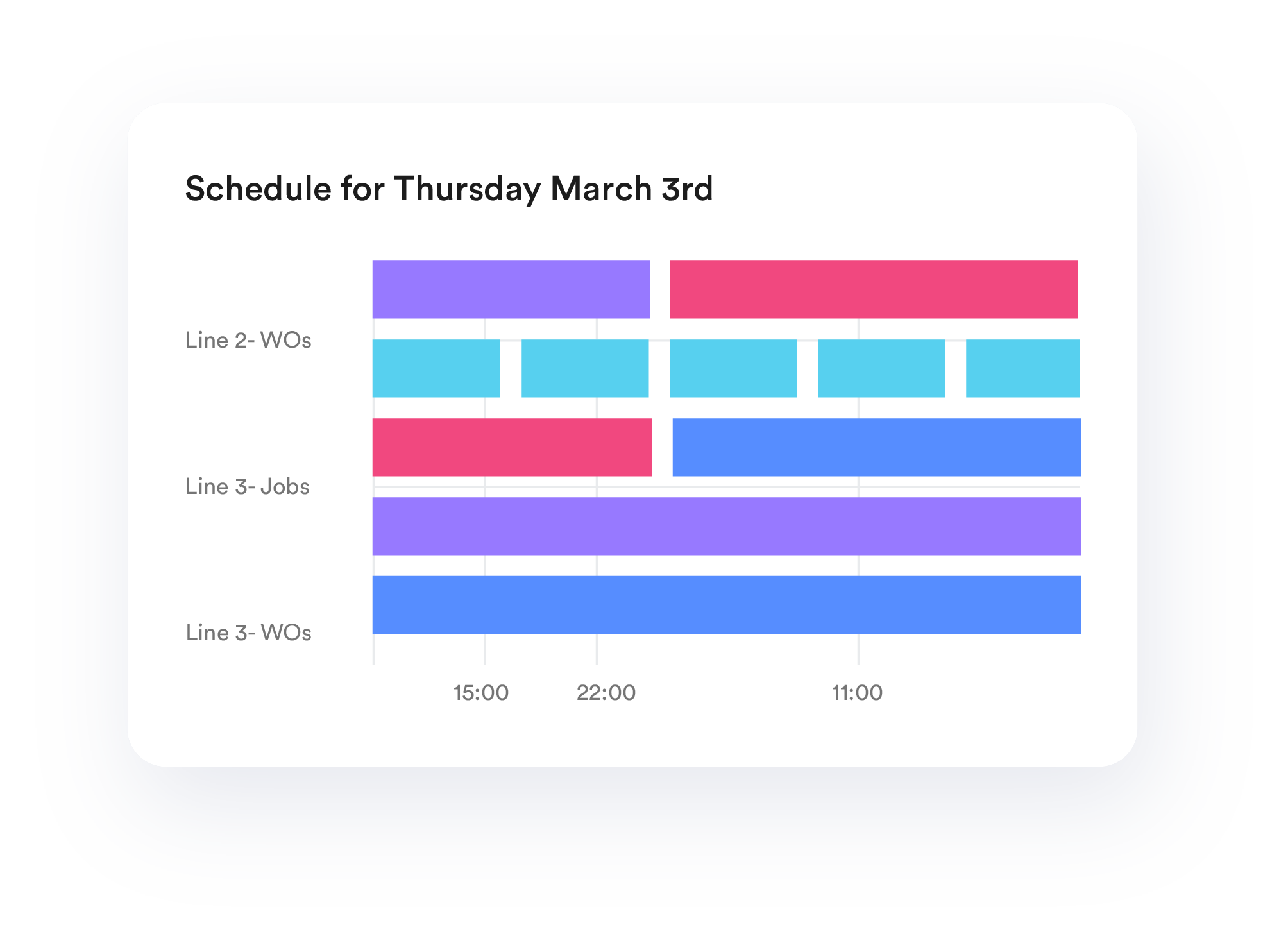

Work Order Scheduling

Optimize the use of existing and resources, with comprehensive scheduling. Cross-reference production schedules, labor schedules, and work order schedules to take advantage of optimal conditions for maintenance activities.

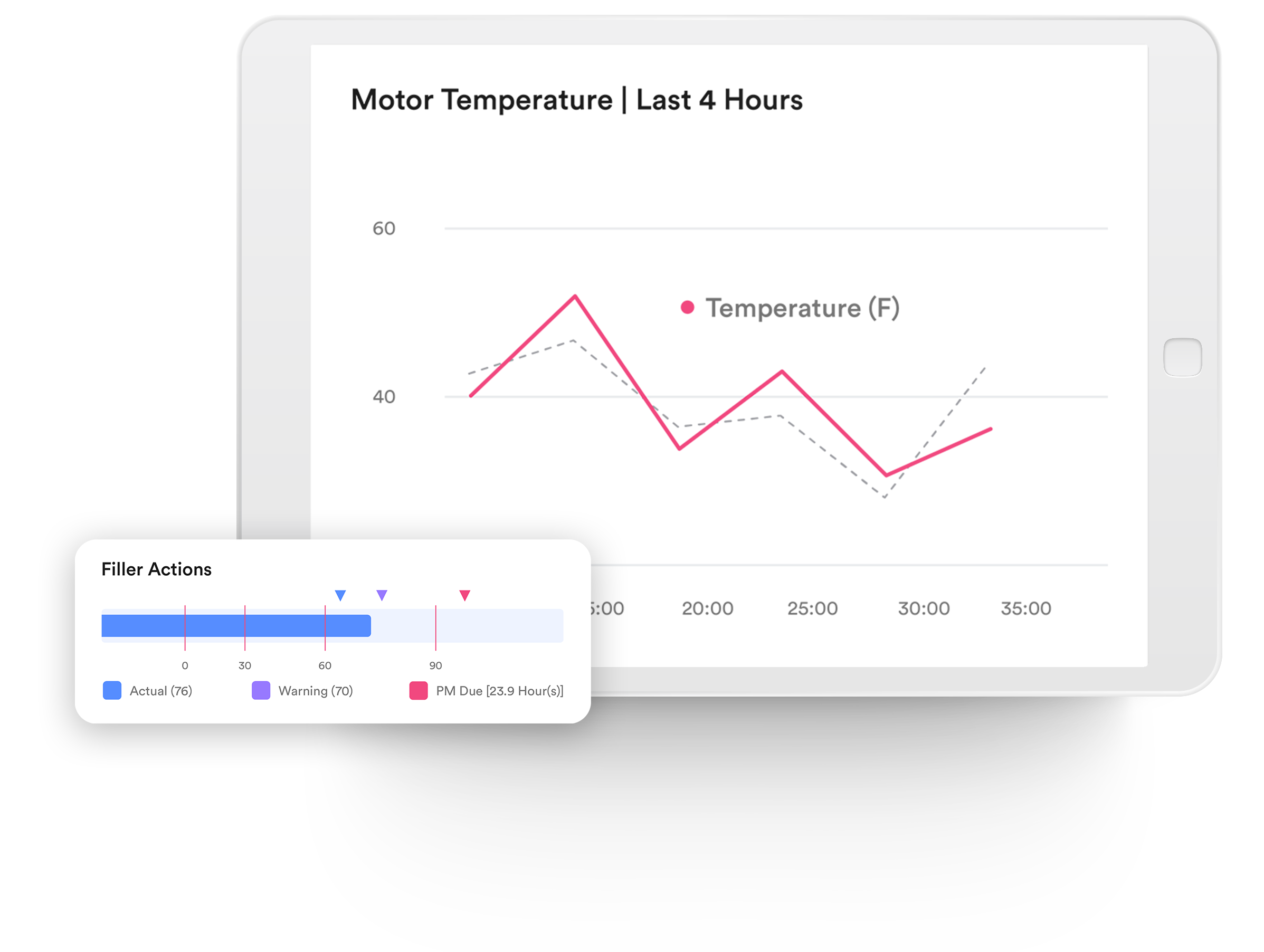

Predictive Maintenance

Identify potential equipment failures before they are catastrophic. TrakSYS predictive maintenance software helps you track key indicators, including Vibration; Temperature; Oil Analysis; Amperage; Differential Pressure.

Reduce unplanned downtime with condition-based asset management.

Metrics & Reporting

Gain visibility into maintenance operations, including status of work orders, on-time completion, and Response and Wrench-time to return equipment to a good running state. Quickly identify which equipment and root causes require corrective actions to improve equipment performance.

Configurability

Web-based configuration tools and an integrated scripting environment allow the construction of tailored maintenance management solutions without the need for custom code.

Extensibility

TrakSYS is a full manufacturing operations management (MOM) system, with standard function libraries that can be readily adjusted to create focused solutions in a fraction of the time compared to traditional development. This important functionality delivers both rapid deployment and cost-effective extensibility.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.