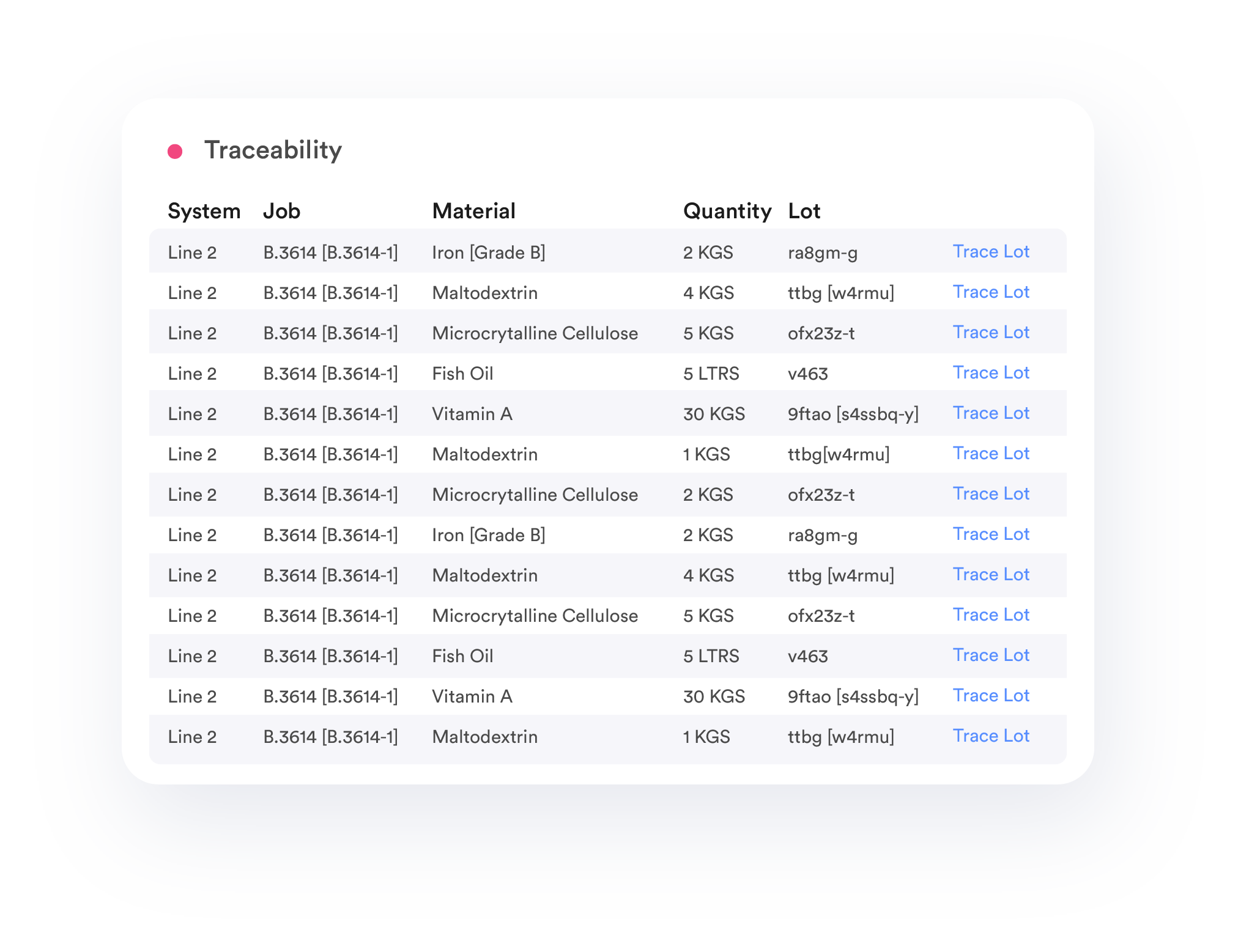

Full Two-Way Traceability

Traceability in Production is Critical to Protecting Consumers and your Brand

For regulated plants, recording, tracking, and tracing the genealogy of raw materials, Work-in-Process (WIP), and go-to-market products is essential to regulatory compliance. Of course, a traceability software solution can do more than help you comply with regulations; when traceability data is providing real-time transparency, it can help you proactively limit the impact of any quality problem before the product is shipped.

Protect Customer Safety and Brand Reputation

Comply with Regulatory Requirements

Improve Inventory Accuracy

Minimize Recall Time and Costs

A Full Two-Way Traceability Solution

The TrakSYS traceability software solution captures a digital record of material and activities through the production lifecycle. TrakSYS can also integrate with ERP and LIMS to provide an expanded traceability chain from raw material sources through quality control and finished product release to customers. With TrakSYS, tracing goods backward along the supply chain, or forward along the distribution chain, is accomplished in seconds instead of days with paper-based systems.

Production Lot History

Track material lots, sublots, and consumption through each production step. Manage the assignment of new lot numbers and individual product serialization for more granular lot traceability, making it easier to isolate quality, warranty or safety issues.

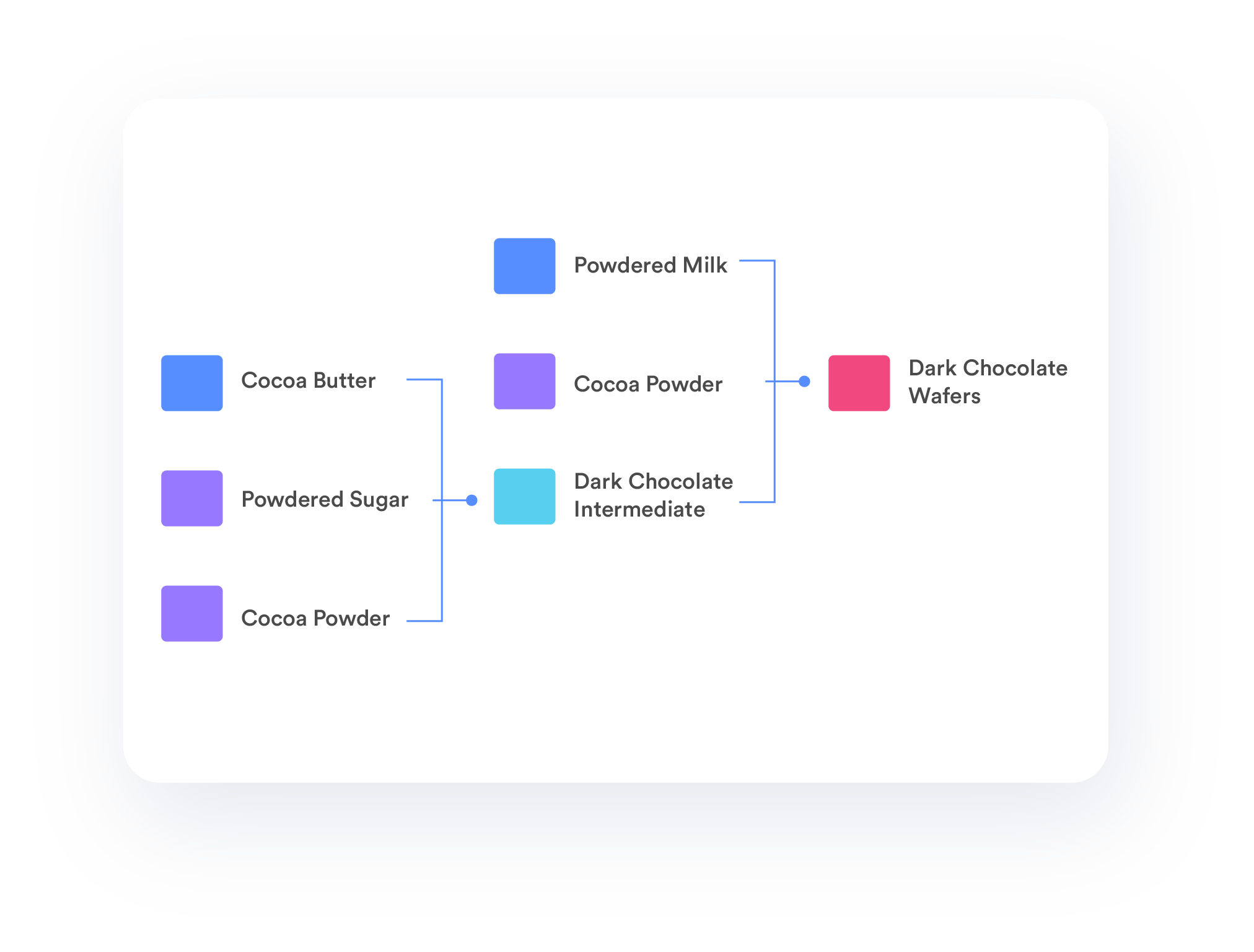

Genealogy

Track product geneology through the production lifecycle including the raw materials, intermediate materials, and finished product stages to expedite investigation of customer complaints, supplier recalls, and other related quality conditions.

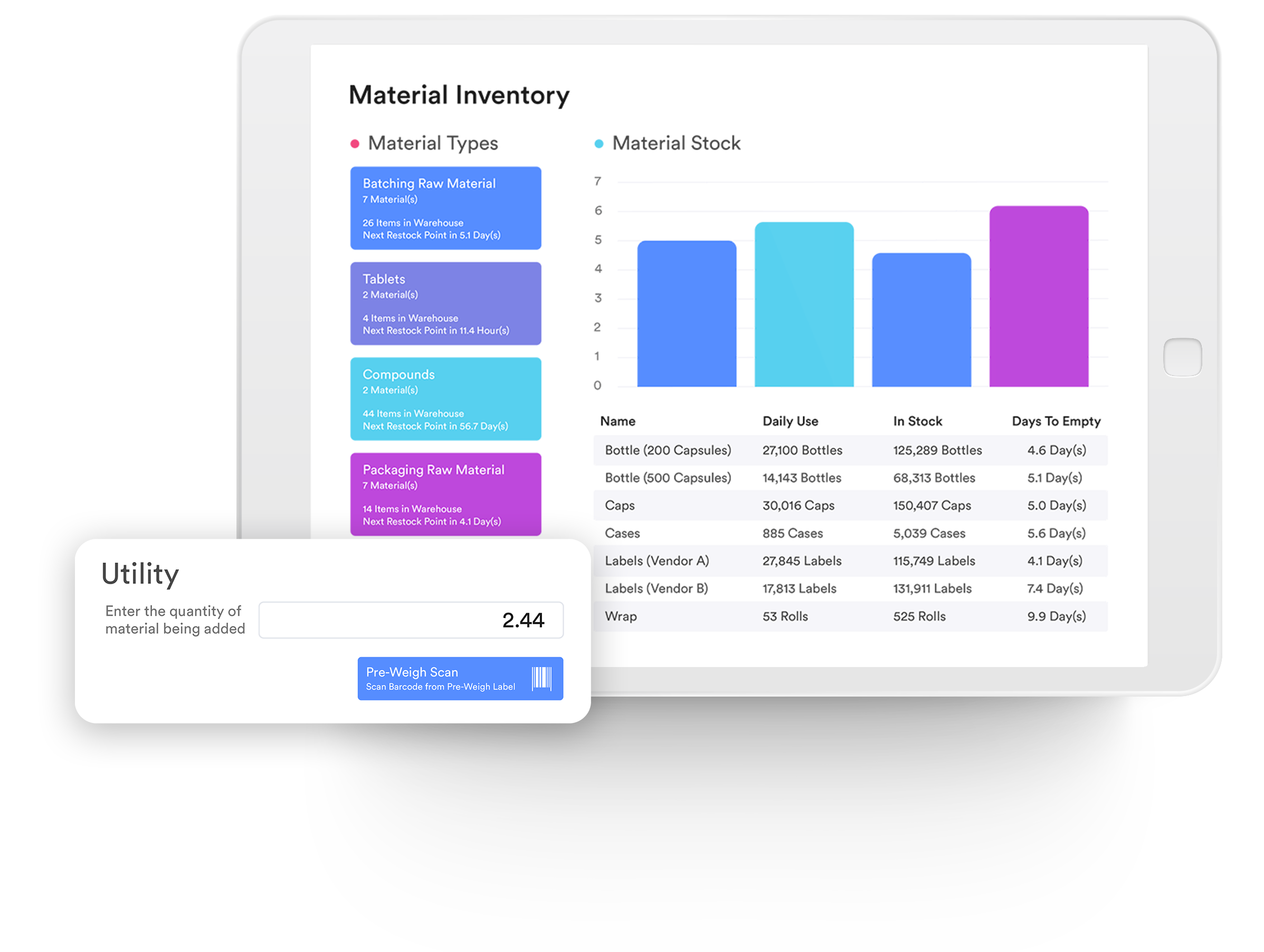

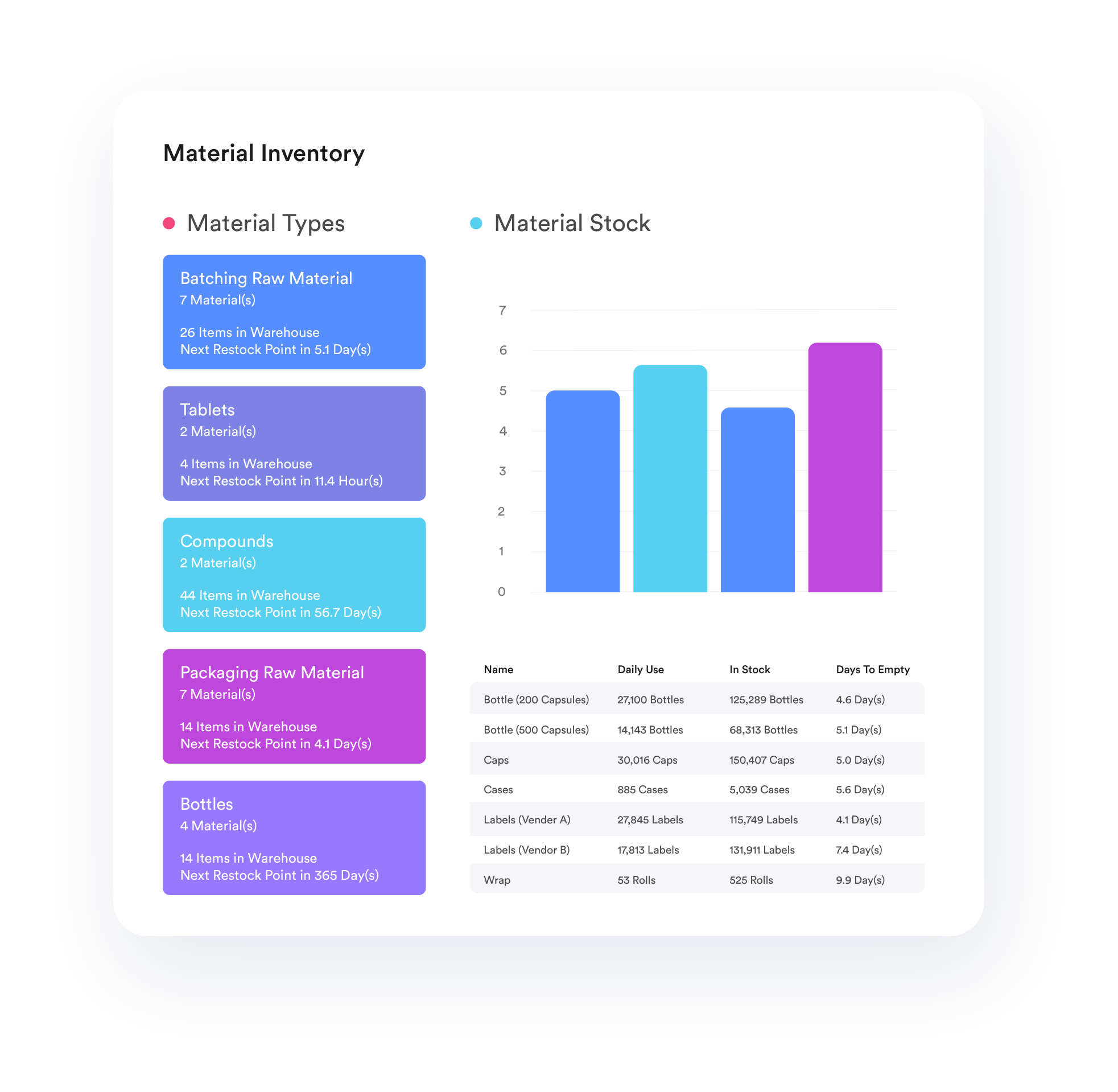

Real-Time Inventory Management

Gain full visibility of material locations, statuses, and interruptions in material flow. Leverage machinery automation to track consumption and maintain inventory accuracy. Track and automate material replenishment to minimize production and delivery delays.

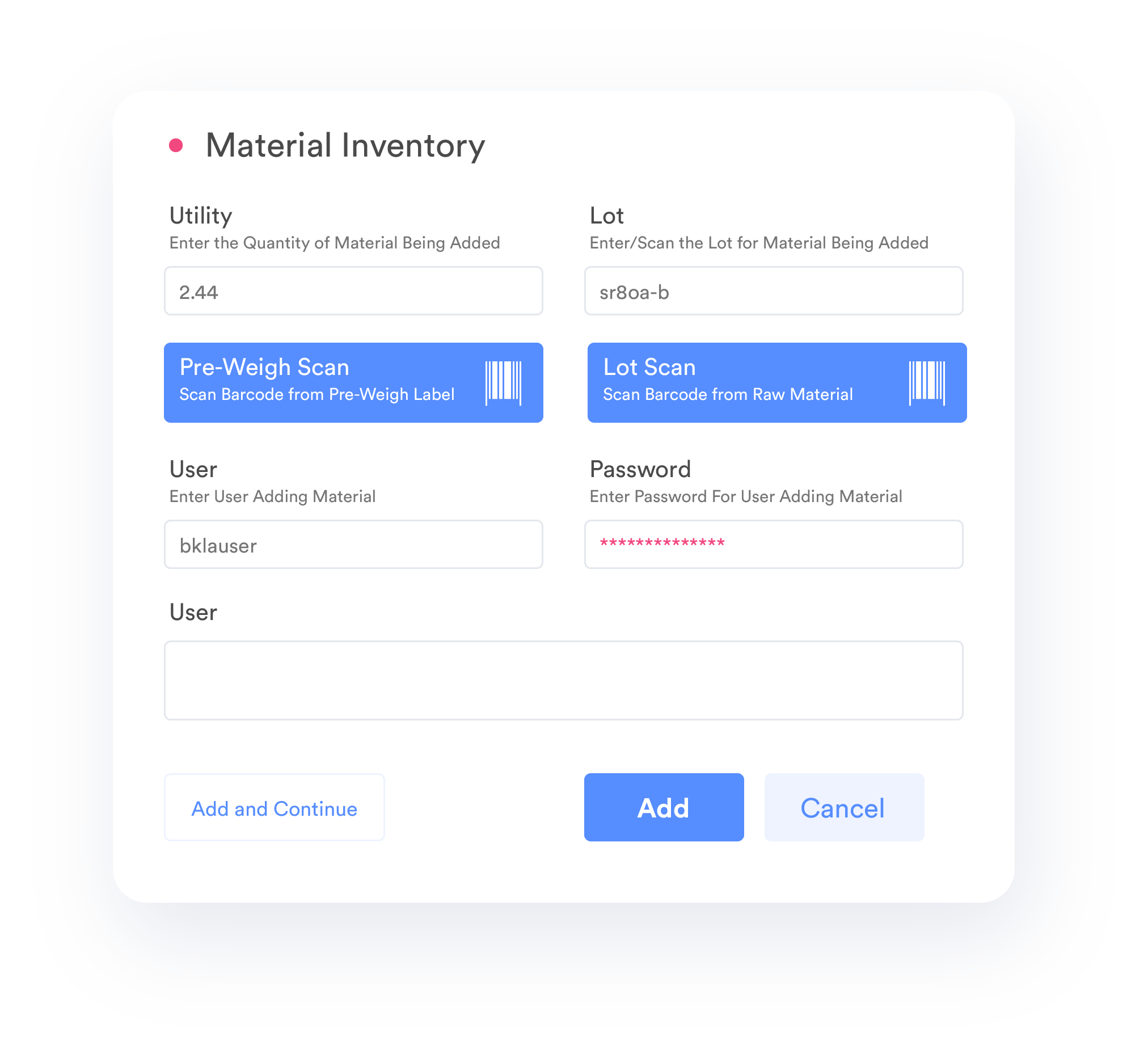

Barcode & RFID Integration

Leverage hardware like 1D and 2D barcodes, Direct Part Marking, and RFID technology to reduce human error and improve productivity.

Configurability

Web-based configuration tools and an integrated scripting environment allow the construction of tailored maintenance management solutions without the need for custom code.

Extensibility

TrakSYS is a full manufacturing operations management (MOM) system, with standard function libraries that can be readily adjusted to create focused solutions in a fraction of the time compared to traditional development. This important functionality delivers both rapid deployment and cost-effective extensibility.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.