TrakSYS for Automotive

Unified Operations. Unparalleled Success.

Automotive Manufacturing Solutions Trusted Worldwide

The TrakSYS MES software platform has been deployed at thousands of factories in over 100 countries, including many automotive manufacturers.

Optimize Operations Across Your Value Stream

As a manufacturer in the automotive industry, you face significant challenges: effectively managing logistics and supply chain, labor, and sustainability initiatives, to name a few. The more areas of the value stream working together the better the outcome. With a real-time manufacturing operations management solution, operations such as Inventory Management, electronic Kanban, machining, powertrain, assembly, body shop, and paint can be managed as a pull-through and coordinated process to significantly reduce productivity losses. TrakSYS is up to the challenge.

Improve Production Quality

Full History & Traceability

Increase Maximum Productivity

Give Customers Visibility

How TrakSYS Helps You Monitor and Control Production Throughout Your Supply Chain

With its configurable, flexible, and scalable workflow management engine, TrakSYS readily leverages existing assets and infrastructure for the optimal management and execution of automotive manufacturing operations. Here’s how:

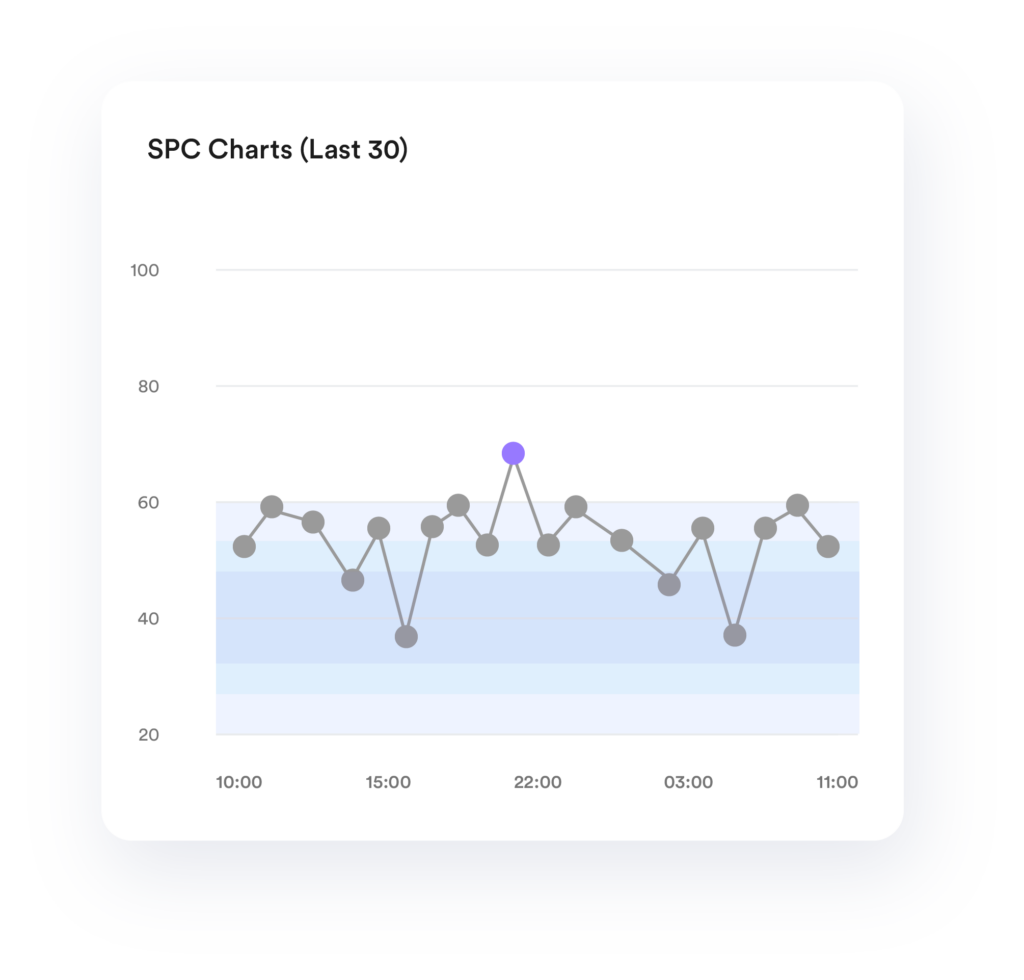

Quality Assurance

Improve product quality with Statistical Process Control (SPC) and real-time data to respond to out-of-compliance events.

History and Traceability

Collect manufacturing information for each part, including the date/time of each operation, measurements taken, batch, and any treatment or finishing information.

Automotive Production Process Analysis

Generate detailed reports by querying the TrakSYS database, including item tables, SPC tables and the quality data gathered from machines.

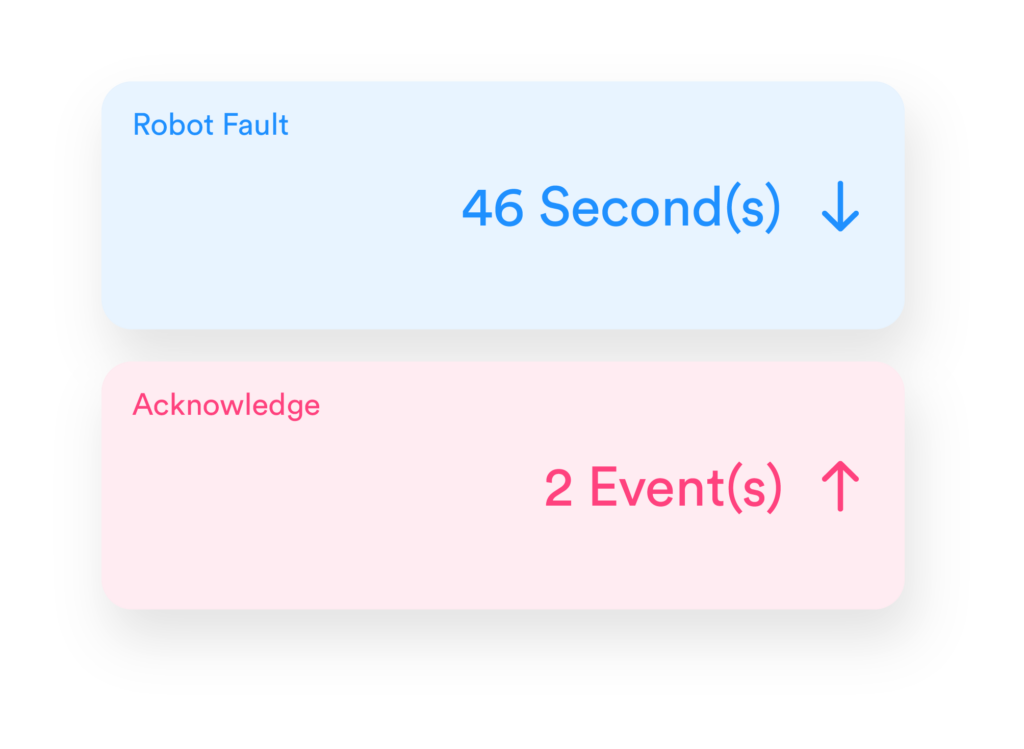

Increased Productivity

Increase productivity through measurement such as OEE and TEEP, and automated corrective and preventive action using tasks and journals.

Customer Visibility

Give customers visibility into production reports generated by TrakSYS — including full process workflow and an overview of the life of each part.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.