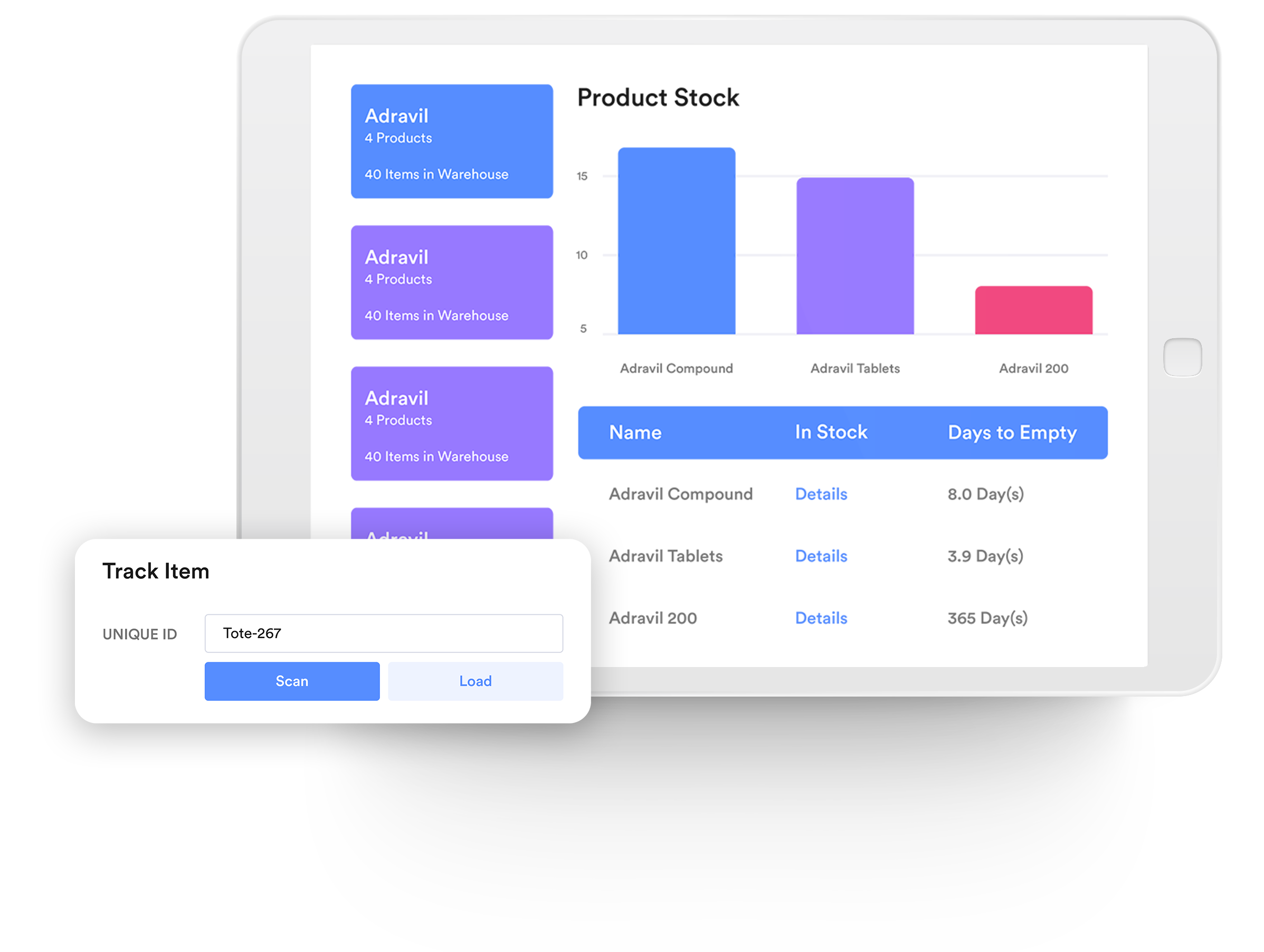

Real-Time Inventory Management

You Want to Maintain Tight Control of Inventory to Increase Production Efficiency and Reduce Working Capital Requirements.

TrakSYS provides real-time insight into material status and location through warehousing, production, and distribution.

Improve Inventory Accuracy

Reduce Write-Downs

Decrease Lead Times

Monitor Supplier Quality

Download the Inventory Management Brochure

We’re committed to your privacy. Parsec uses the information you provide to us to contact you about our relevant content, products, and services. You may unsubscribe from these communications at any time. For more information, check out our Privacy Policy.

Inventory Tracking and Material Management Throughout Your Enterprise Use TrakSYS

Use TrakSYS inventory management software to maintain inventory accuracy, optimize budgets and spending, and streamline production planning. In addition, TrakSYS can provide two-way traceability and genealogy from the product made to materials consumed, or materials consumed to products affected.

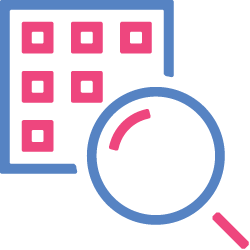

Raw Materials

Gain full visibility of material locations, statuses, and interruptions in material flow. Reduce delays caused by inventory queues which are often a result of inadequate communication.

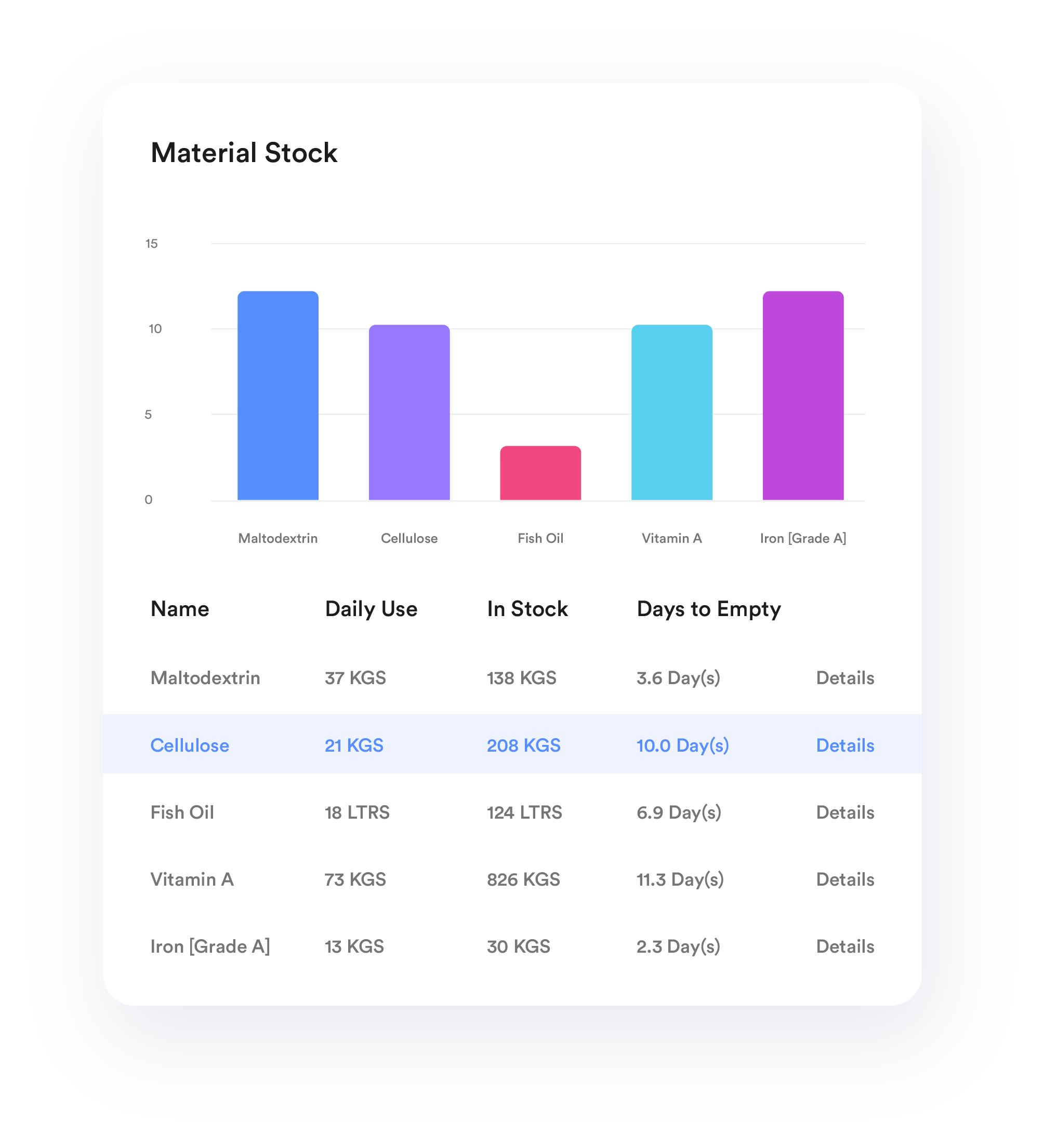

Production Planning and Scheduling

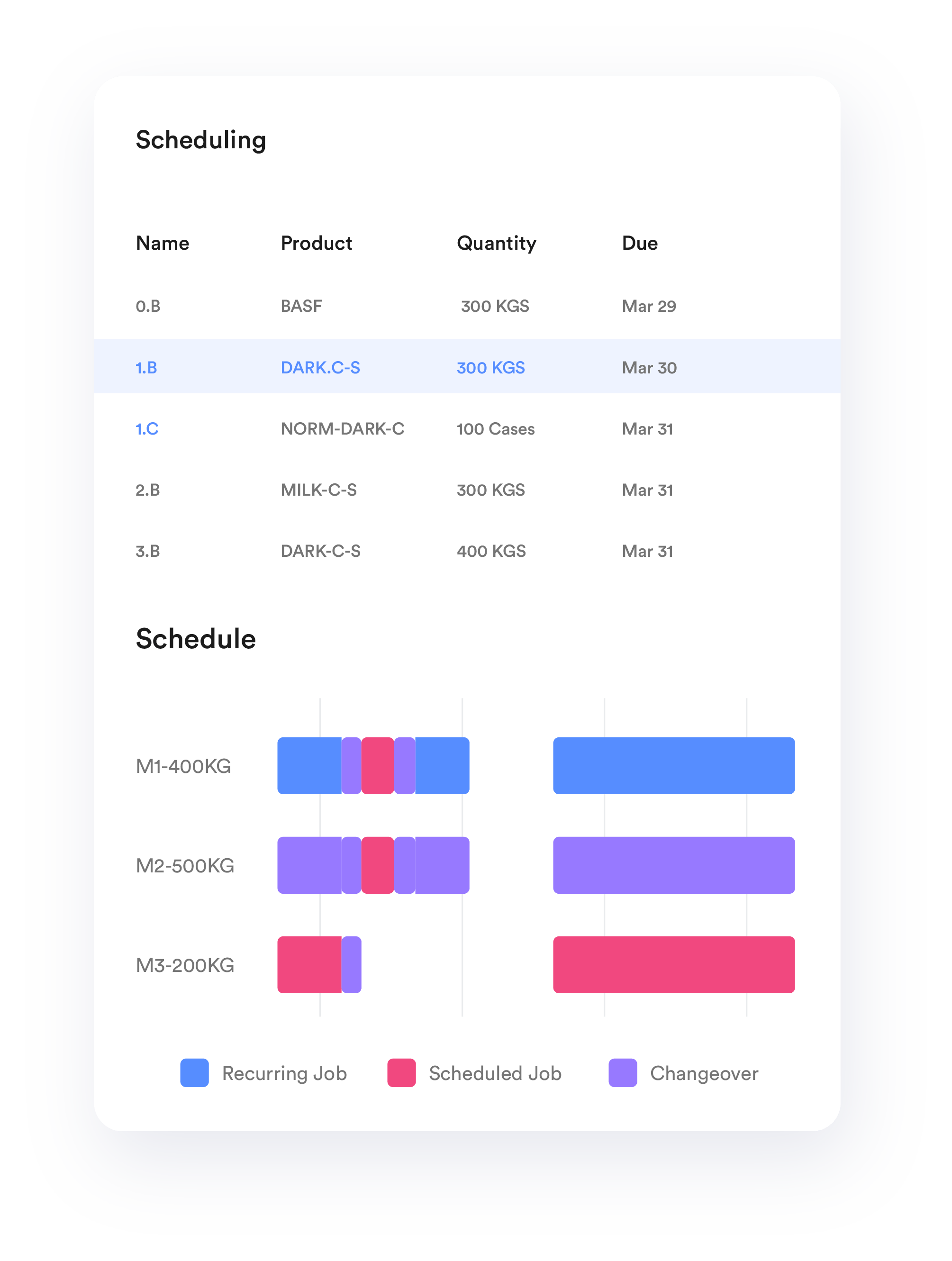

Work-in-Process

Gain full visibility of material locations, statuses, and interruptions in material flow. Reduce delays caused by inventory queues which are often a result of inadequate communication.

Finished Goods

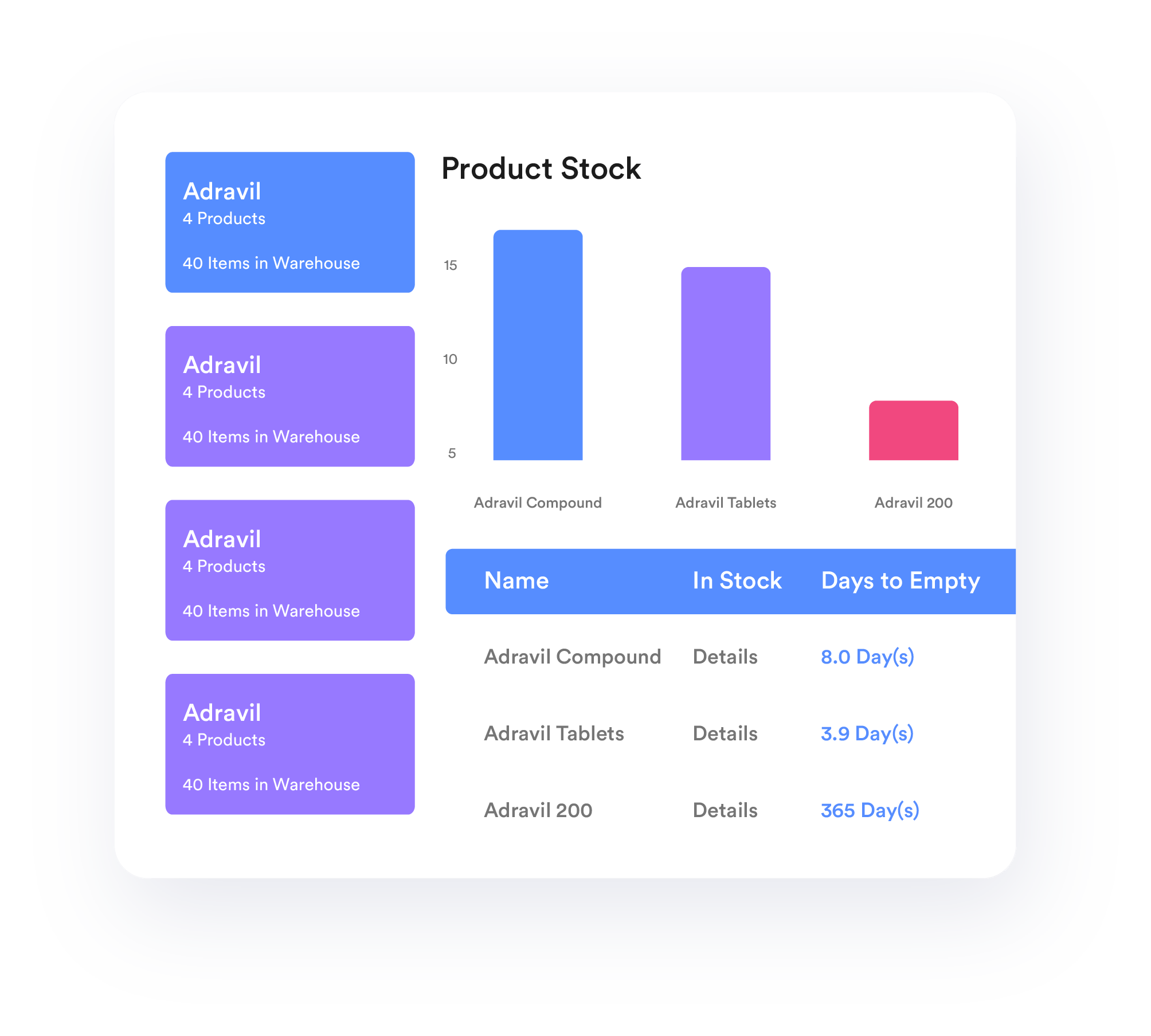

Determine quantities required to fulfill orders. Real-time exception reporting for late and partial quantities. Stock-out predictions based on usage patterns.

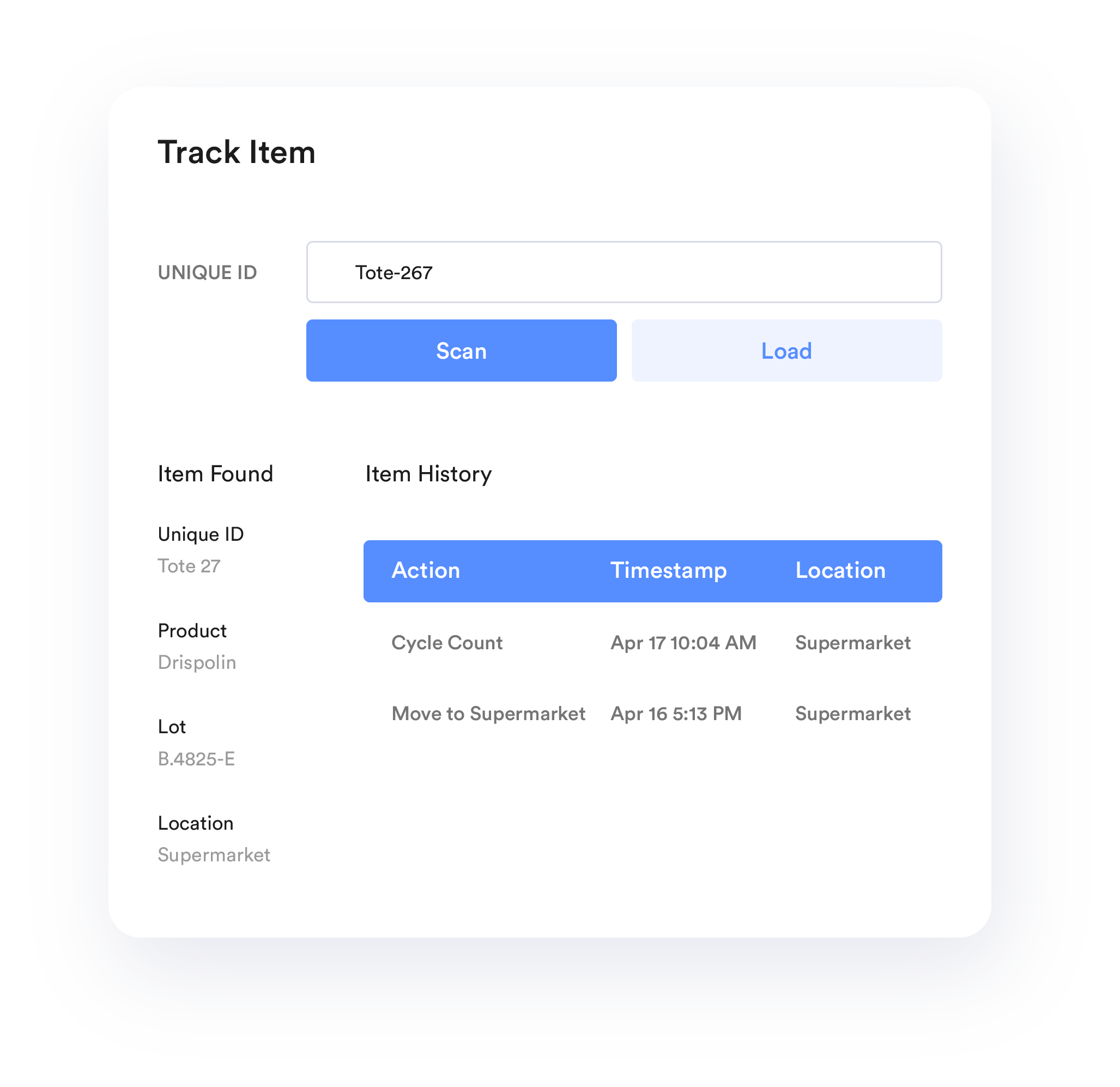

Material Traceability

Track materials throughout production, including Supplier, Lot Code, Process Route, Employee Touches, Dates/Times, Quality Test Results, Process Parameters, etc.

Eliminate guesswork with accurate, data-driven inventory insights.

Metrics & Reporting

Gain visibility into scheduling & warehouse inventory metrics to improve supply chain performance. Quickly determine areas of the process that require corrective action to decrease order-to-ship lead-times and improve on-time delivery performance.

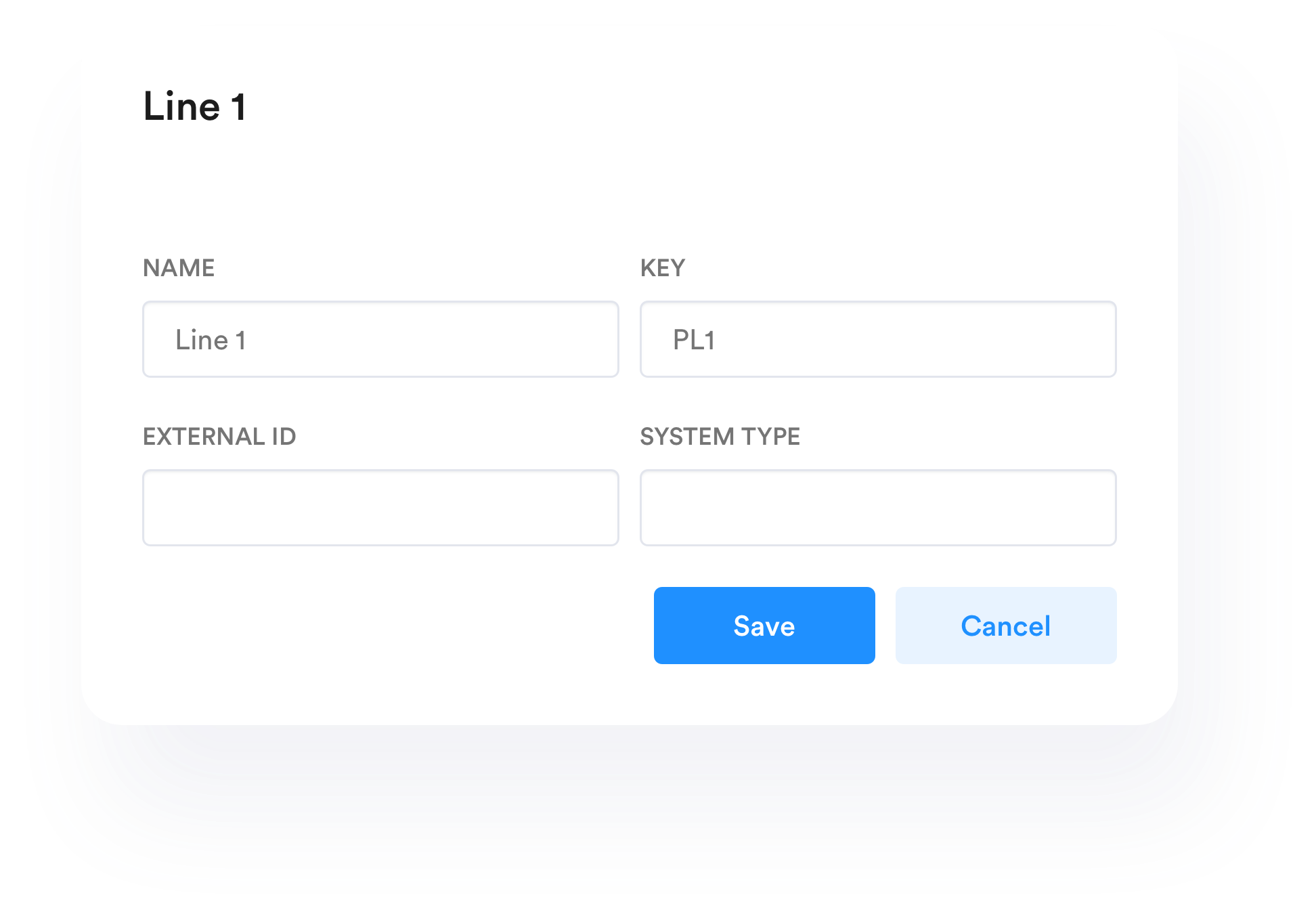

Configurability

Web-based configuration tools and an integrated scripting environment allow the construction of tailored maintenance management solutions without the need for custom code.

Extensibility

TrakSYS is a full manufacturing operations management (MOM) system, with standard function libraries that can be readily adjusted to create focused solutions in a fraction of the time compared to traditional development. This important functionality delivers both rapid deployment and cost-effective extensibility.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.