Batch Management

Batch Management is Critical to Process Industries

TrakSYS offers versatile recipe and Batch Management capabilities designed for executing batching operations in both automated and manual operations. The TrakSYS batch management solution follows ISA-88 standards and makes it possible to manage recipes, execute batch functions, enforce SOPs/tasks, allocate assets, and track materials and labor. A complete electronic audit trail of transactions can be available to meet 21 CFR Part 11 Compliance, cGMP, and the most stringent EBR requirements.

Improve Product Quality

Maximize Asset Utilization

Manage Regulatory Compliance

Lower Cost

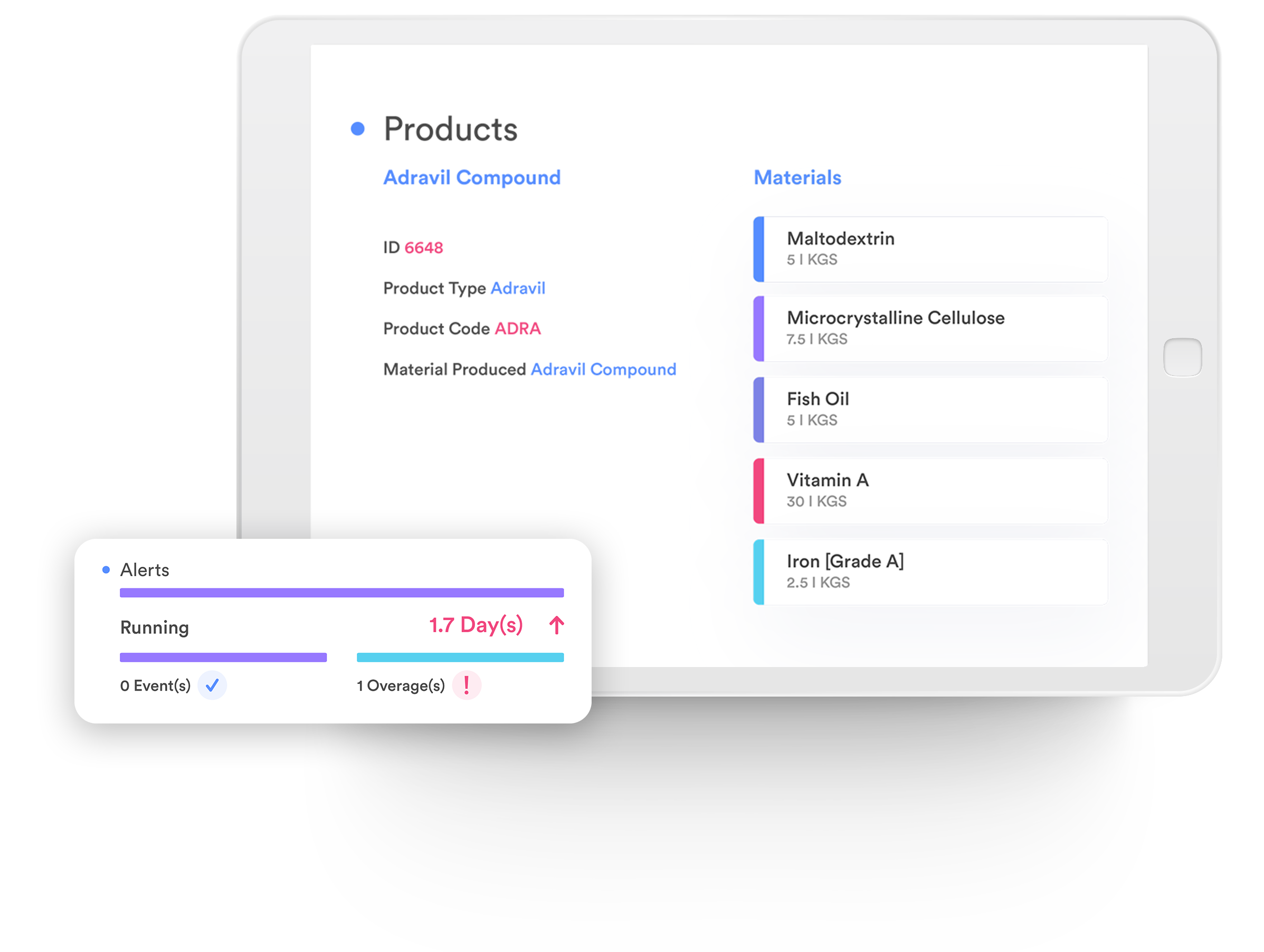

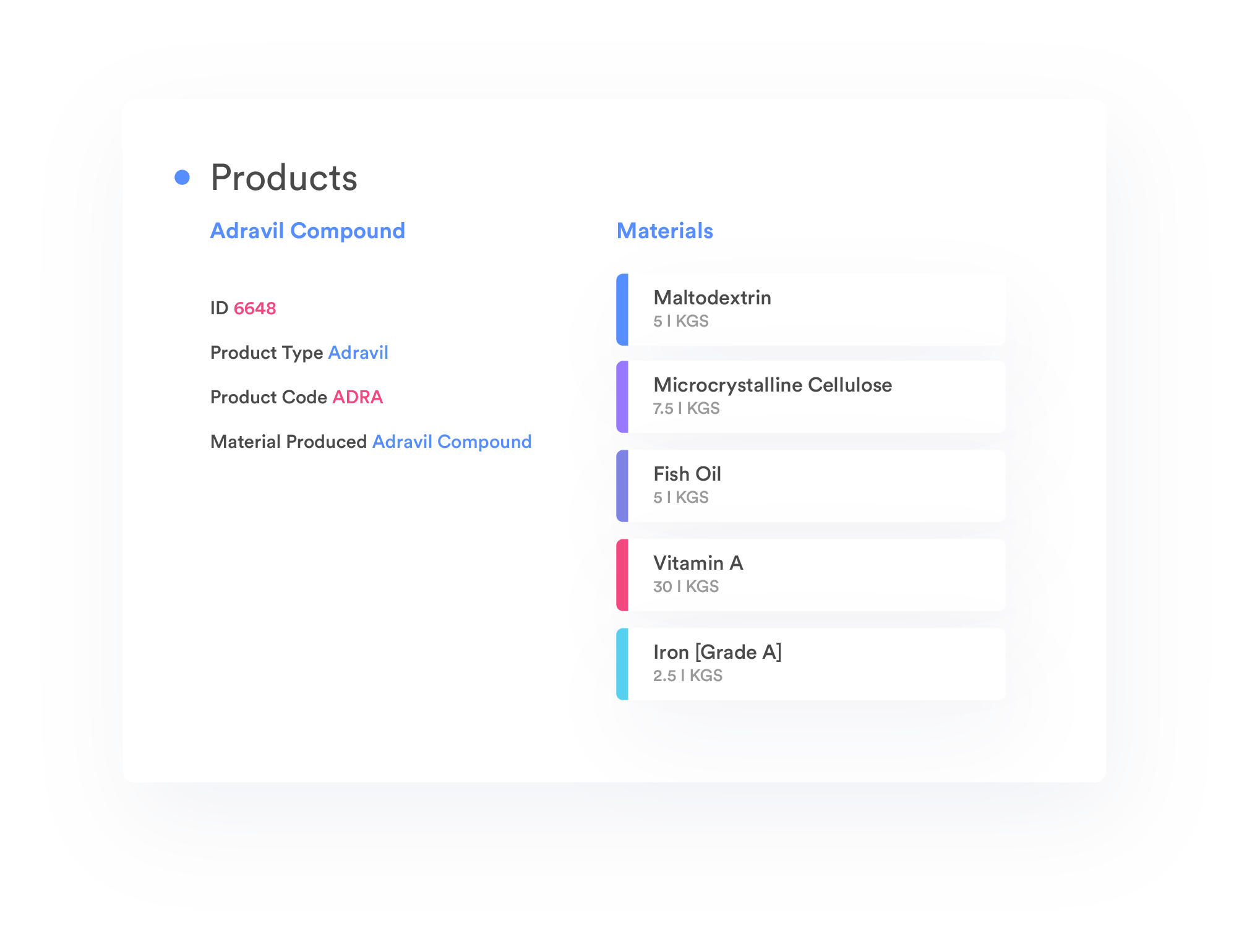

Recipe Management

Configure recipes and procedures, or interface with information stored in ERP to provide the shop floor with instructions for how to complete the batch.

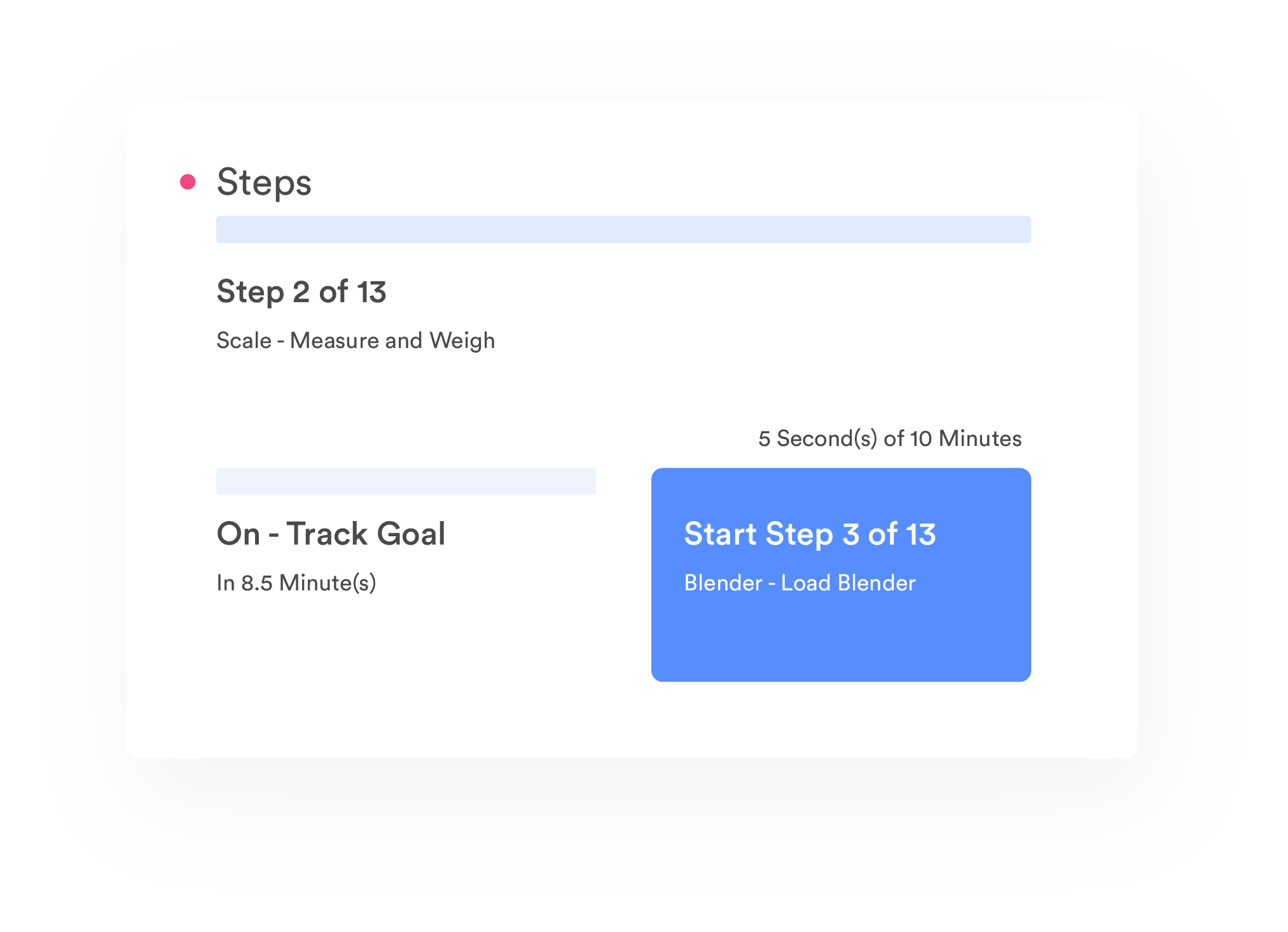

Pre-Weigh & Execute Batch Steps

Define batch functions, sequential/parallel steps, and tasks (e.g. setup, manual checks, quality checks, sign-off, etc.) to enforce standard procedures.

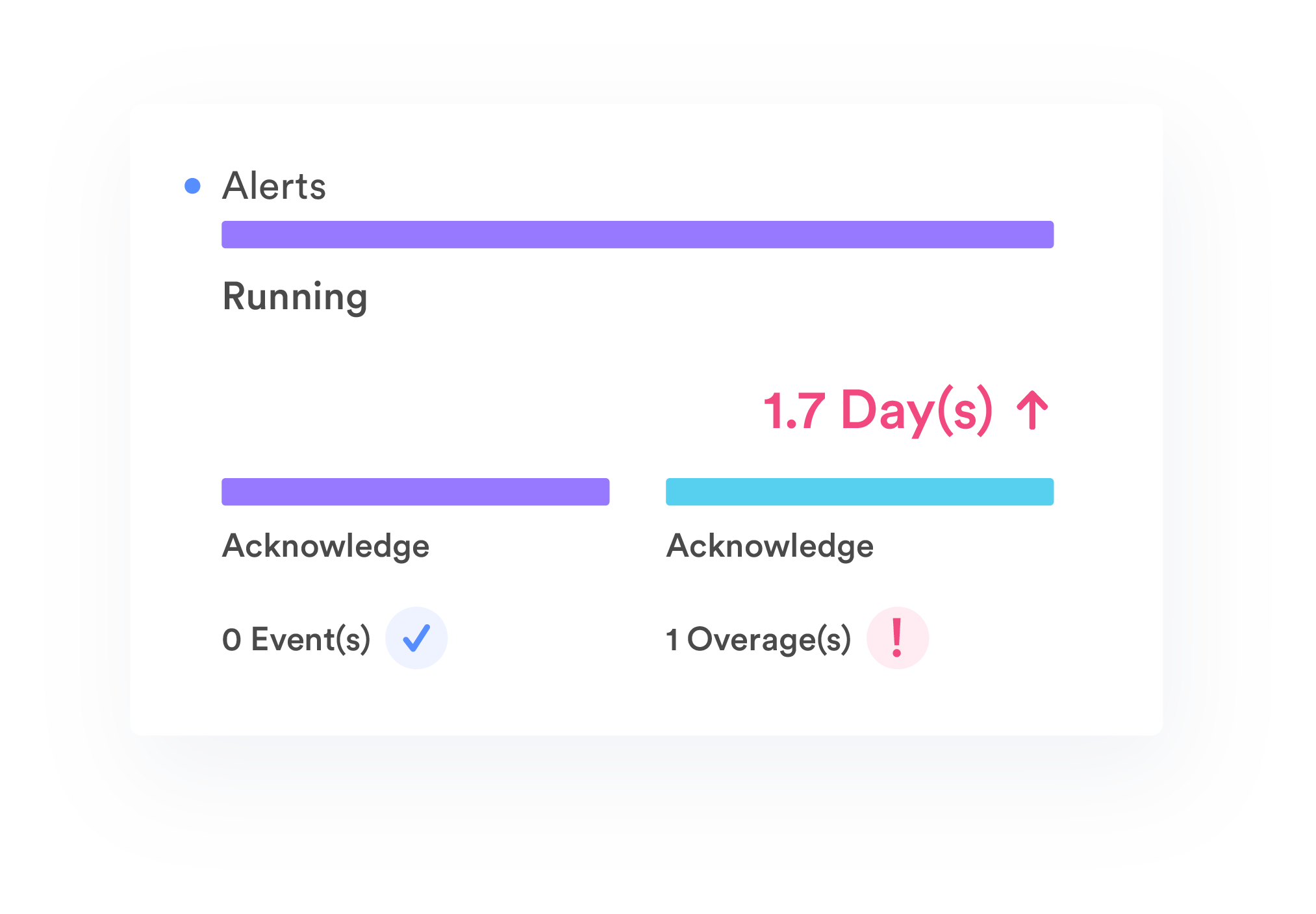

Track and Manage Events and Overages

Connected to existing automation infrastructure, TrakSYS provides a clear view of what is happening on the plant floor and informs of events requiring attention. TrakSYS records specific causes of delays and overages and analyzes the trends to determine how to reproduce your golden batch.

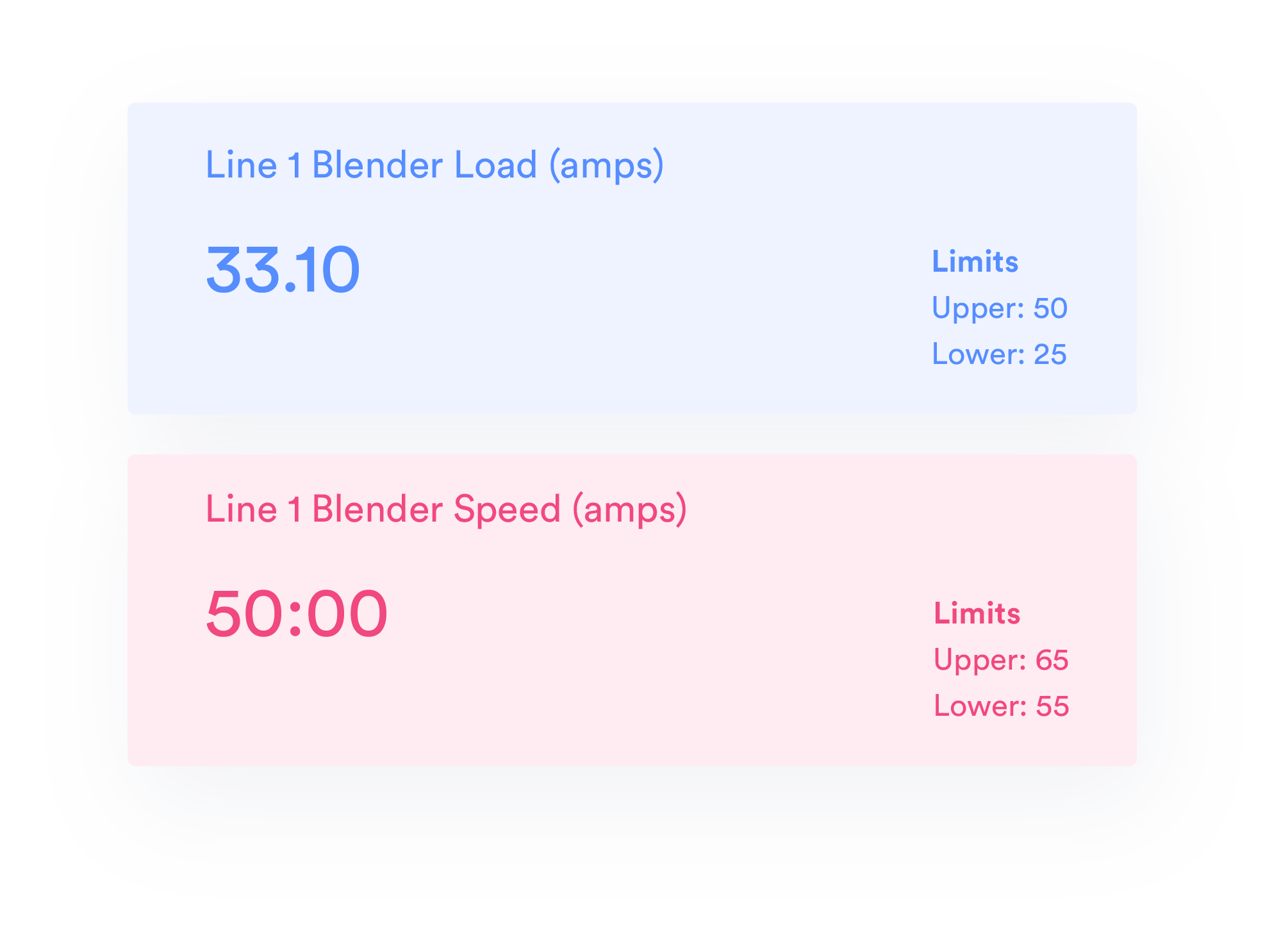

Monitor Critical Parameters

Connect to automation to record and retrieve time-series production and process data. Data Historian further enhances Traceability, enabling users to analyze sources of variation, identify process improvement opportunities, and quickly troubleshoot root causes.

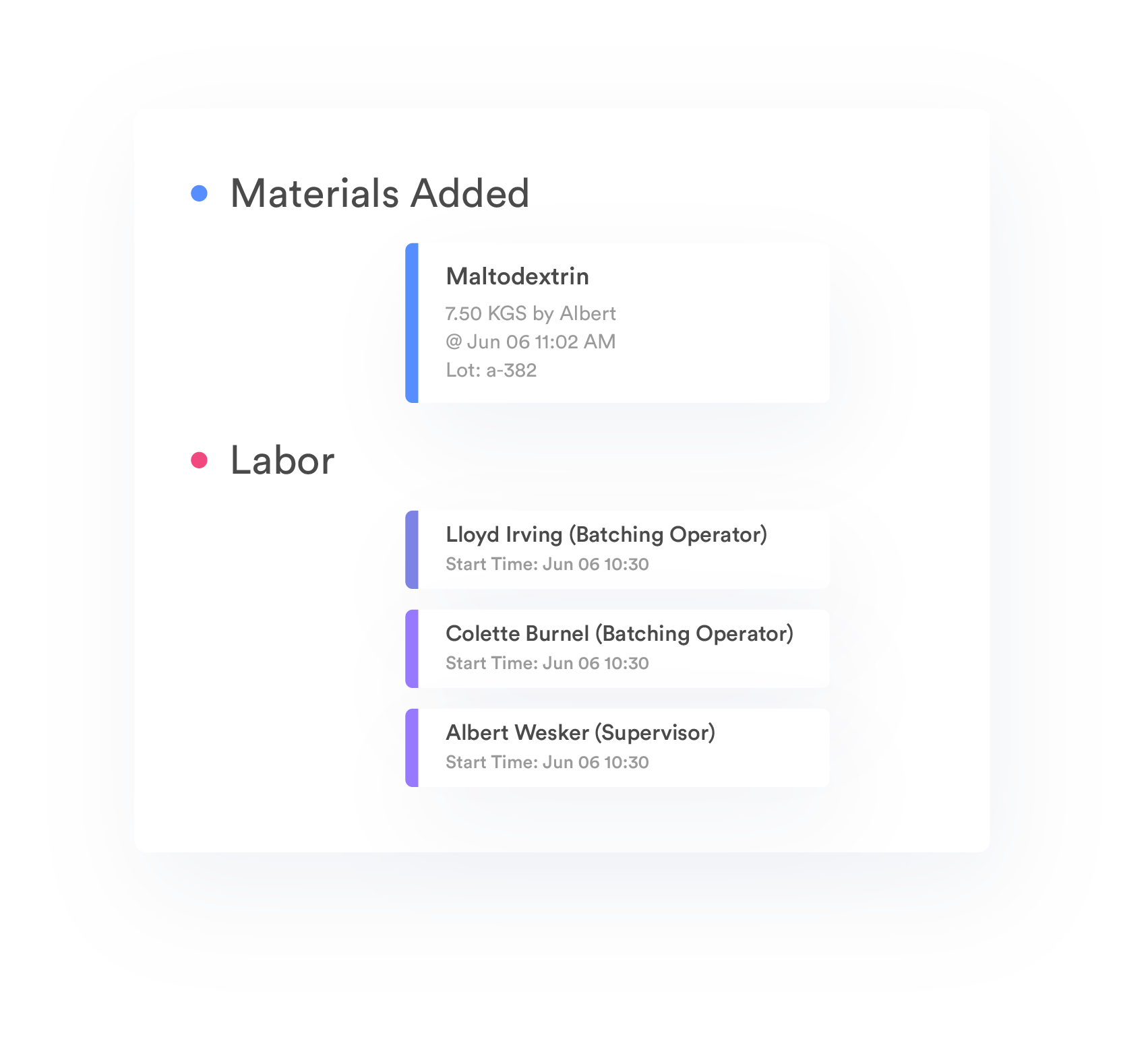

Track Material Consumption

Track suppliers, lot numbers, and quality parameters to provide traceability and benchmark supplier performance. Record material consumption and interface with ERP and WMS to maintain inventory accuracy. Track labor to benchmark performance and establish Best Practices.

Metrics & Reporting

Using extensive analytics, workflow engine, and dashboards of TrakSYS, detailed user-definable reports and electronic batch records (EBRs) can be generated with ease. A complete electronic audit trail of your transactions can be available to meet 21 CFR Part 11 Compliance and the most stringent EBR requirements.

Configurability

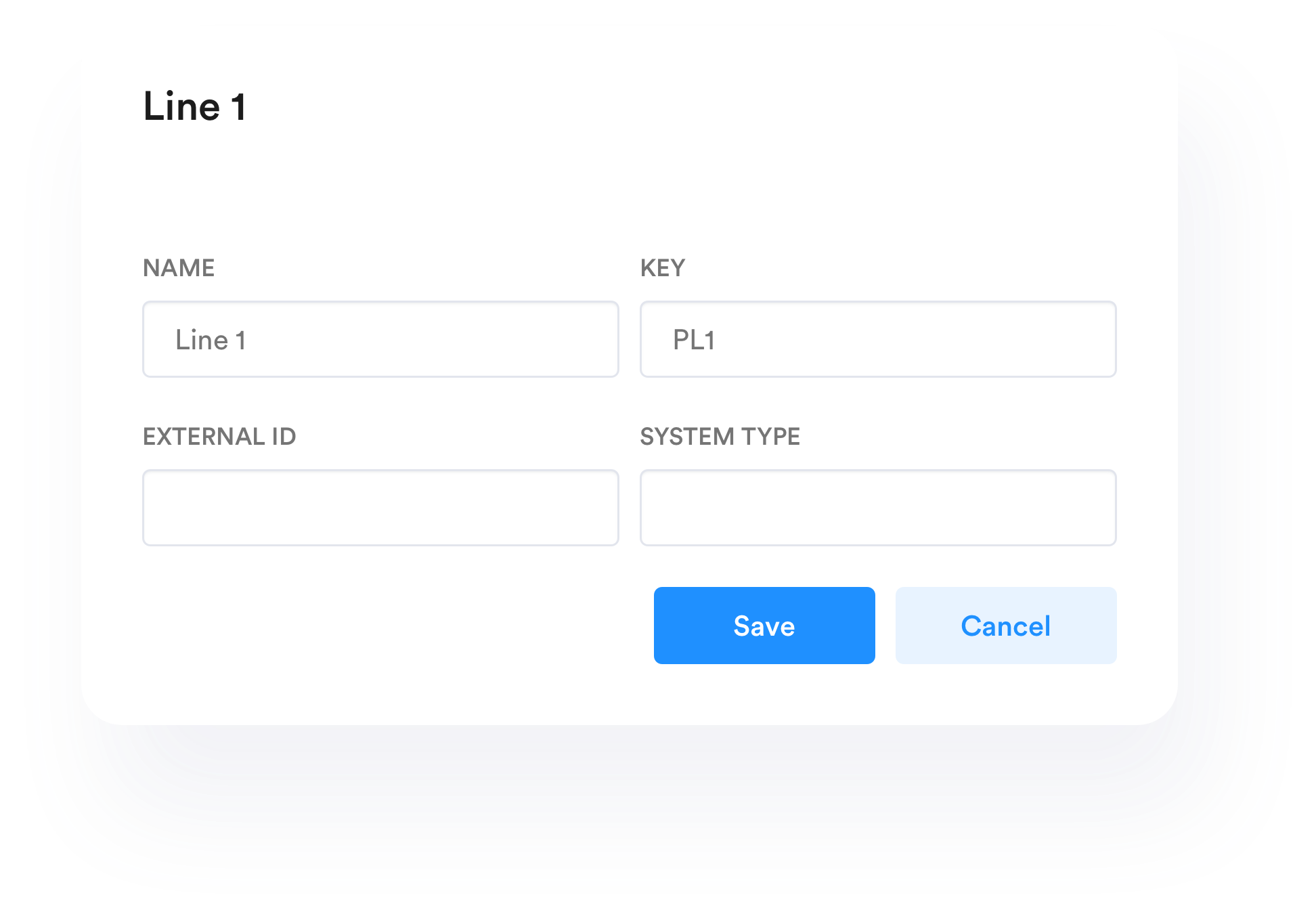

Web-based configuration tools and an integrated scripting environment allow the construction of tailored batch management solutions without the need for custom code.

Extensibility

TrakSYS is a full MES software platform, with standard function libraries that can be readily adjusted to create focused batch management solutions in a fraction of the time compared to traditional development.