TrakSYS for Food and Beverage Manufacturers

An Appetite for Optimization

Food and Beverage Manufacturing Software, Trusted by Leading Brands Worldwide

TrakSYS has been deployed at thousands of factories in over 100 countries, including many leading food and beverage processors.

The Recipe for a More Productive and Profitable Operation

As a food and beverage manufacturer, you operate in a fast-paced, highly-regulated environment where profit margins are razor thin. You are also faced with handling an increasing number of product types (SKUs) which means shorter runs with more changeovers, more ingredients to track, etc. Regulatory compliance is always an issue, too, though likely not your biggest concern. You’re focused on optimizing operations to increase quality and productivity, and add a few more points to the bottom line. TrakSYS can help.

Improve Product Quality

Reduce Cost

Ensure Food Safety

Regulatory Compliance

How TrakSYS Helps You Gain Greater Visibility, Knowledge, and Control

TrakSYS helps food and beverage processors enable operational excellence initiatives, meet safety compliance requirements, and support sustainability efforts. Here’s how:

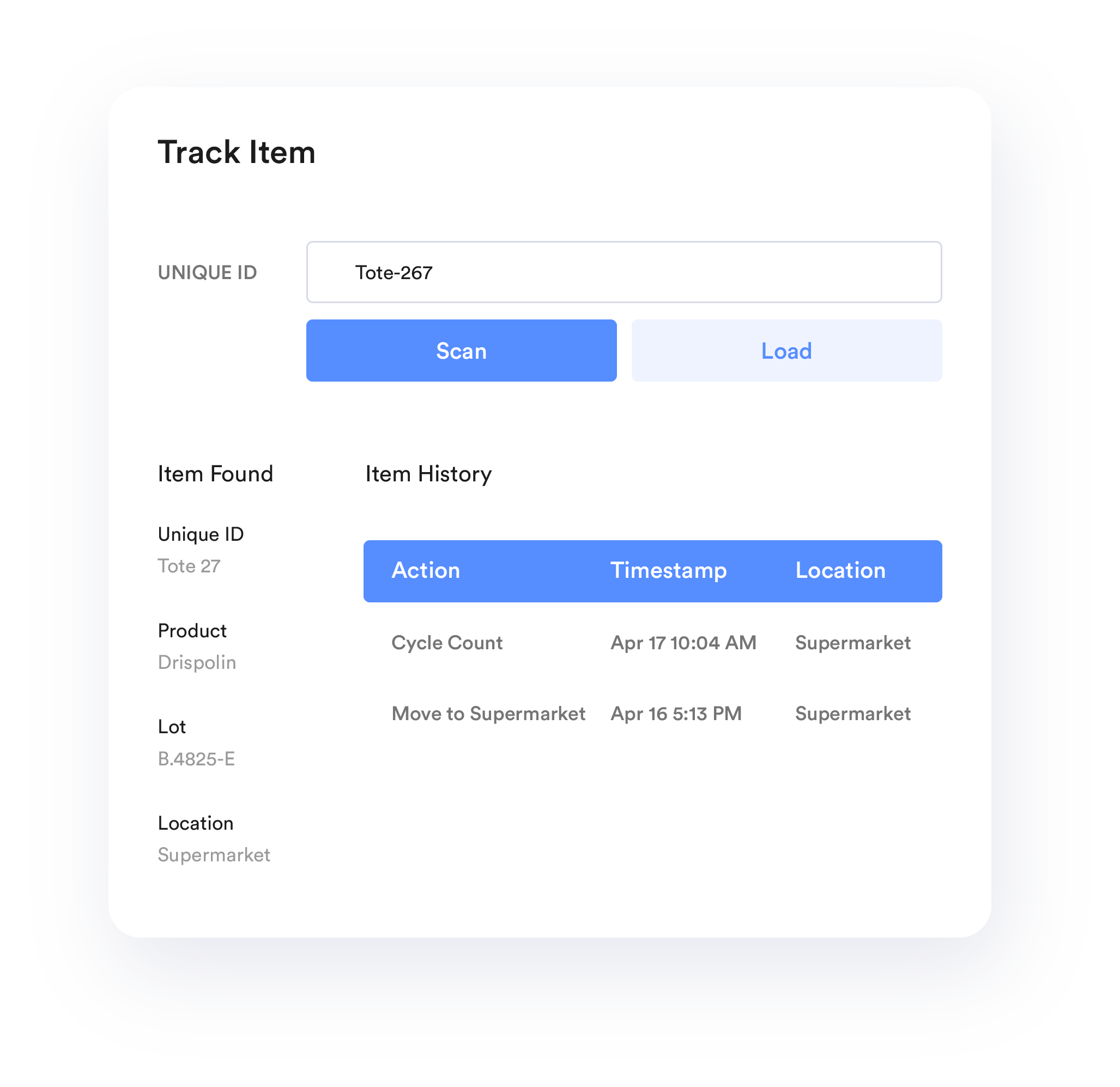

Traceability

Verify supplier materials with digitally tracked and traced production to assure safety and reduce the risk of a recall.

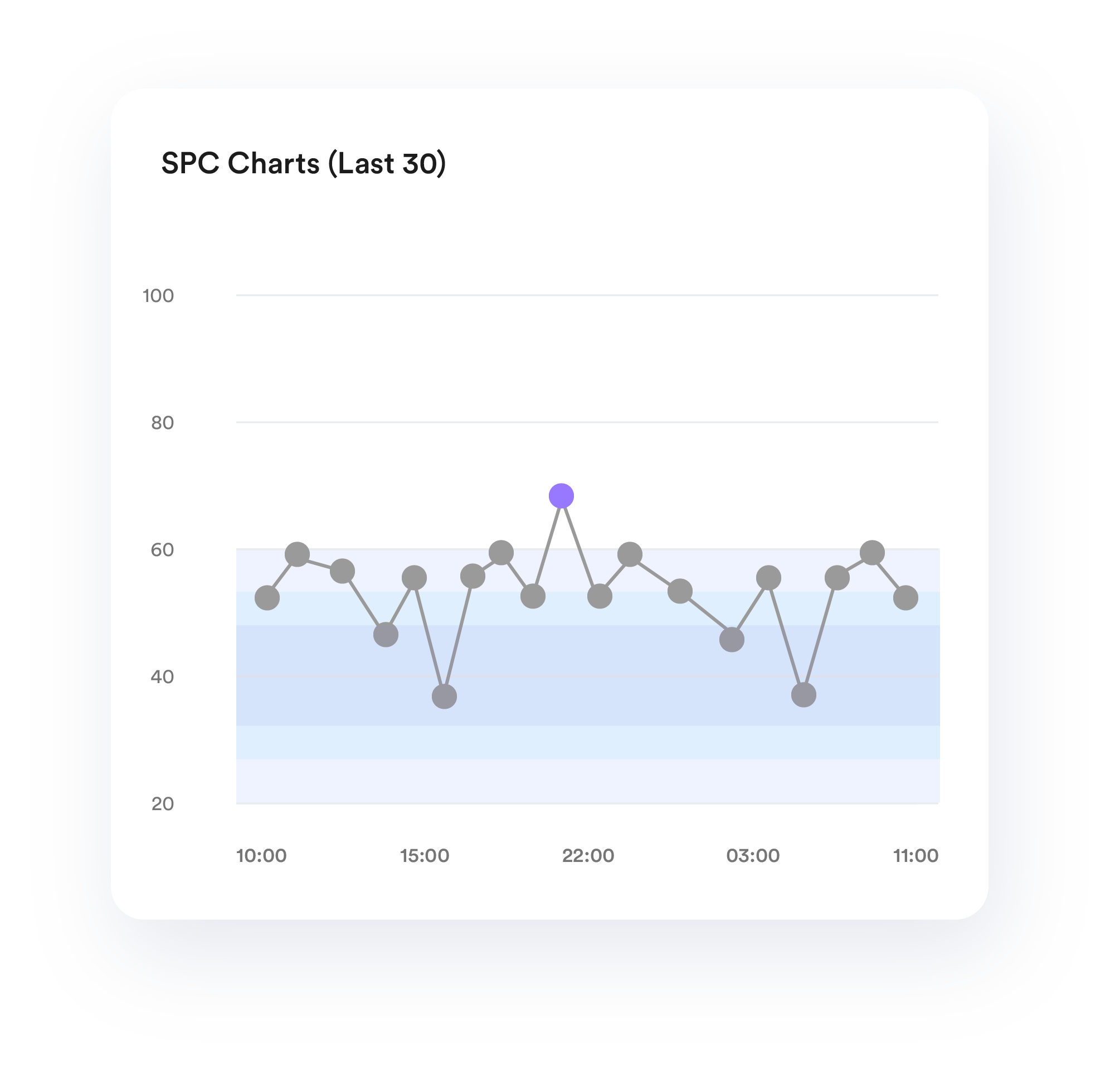

Quality Assurance

Improve quality with Statistical Process Control (SPC) and real-time data to respond to out-of-compliance events

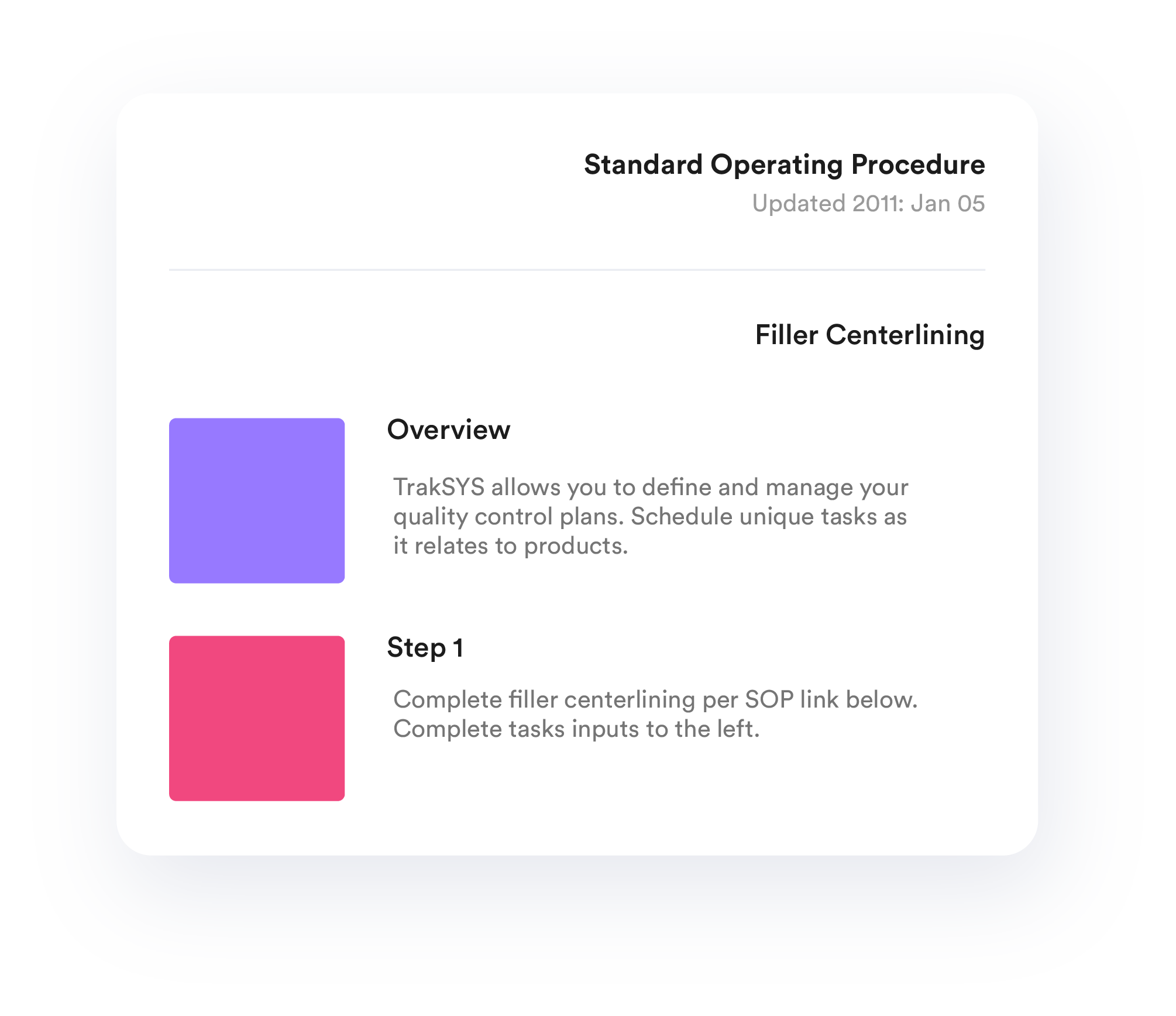

Document Control

Eliminate paperwork with digitally-managed Standard Operating Procedures (SOPs), including full archiving for regulatory compliance.

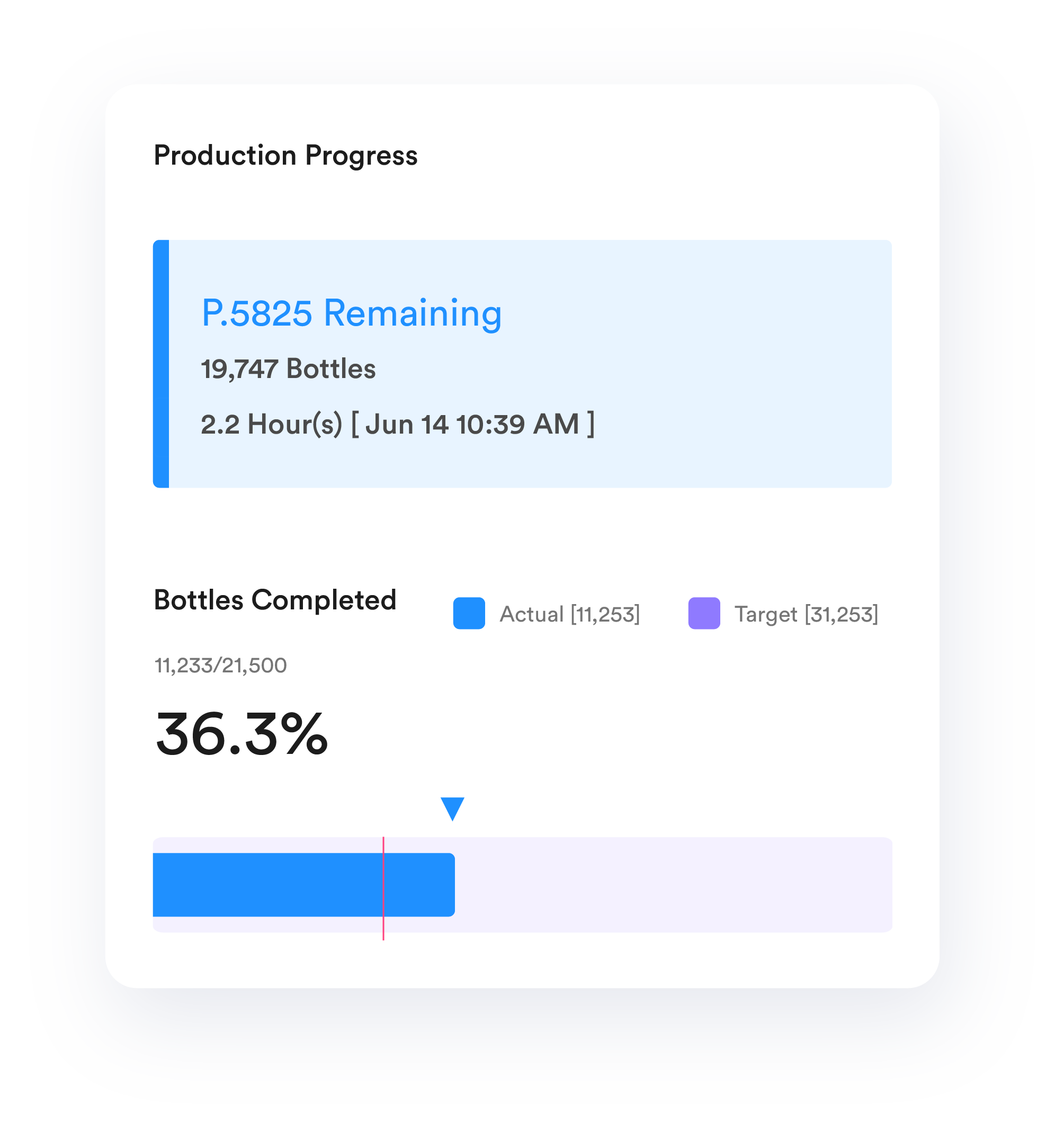

Increased Productivity

Increase productivity through measurement such as OEE and TEEP, and automated corrective and preventive action using tasks and journals.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.