From a Long-Term Continuous Improvement Initiative to a Simple Production Bottleneck - You Need to Understand What is Limiting Your Factory’s Performance

Built on the TrakSYS next-generation manufacturing operations management (MOM) platform, the TrakSYS Real-Time Performance Management solution framework benchmarks performance and productivity, by collecting and aggregating data, to deliver real-time, actionable intelligence for significant productivity improvement – while leveraging your existing assets, resources, and infrastructure.

Improve Productivity

Maximize Capacity

Increase On-time Delivery

Improve Profitability

A Complete Performance Management Solution

The TrakSYS Real-Time Performance Management solution framework offers out-of-the-box functionality designed to provide the insights you need to evaluate the root causes of poor performance in your manufacturing operation. Whether your operations are discrete, continuous or batch, TrakSYS RPM gives you the tools you need — like event tracking, operator task management, alerts, journaling, and more — to optimize performance and profitability across the supply chain.

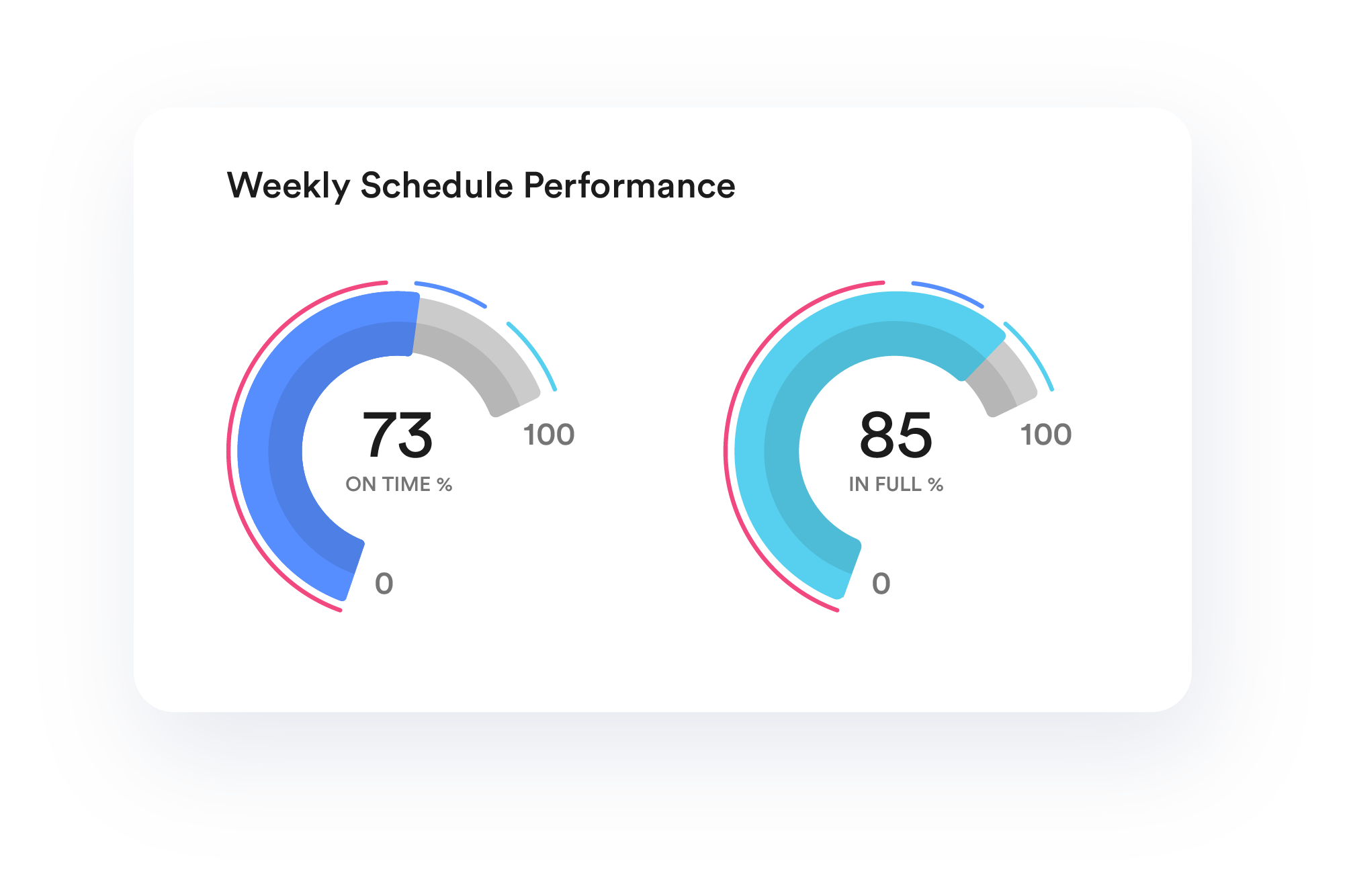

Planning & Scheduling Performance

Planning and scheduling are essential to meeting customer’s on-time delivery requirements. TrakSYS enables analysis of on-time, in-full, and schedule attainment performance metrics for more accurate planning and scheduling, as well as a roadmap for continuous improvement.

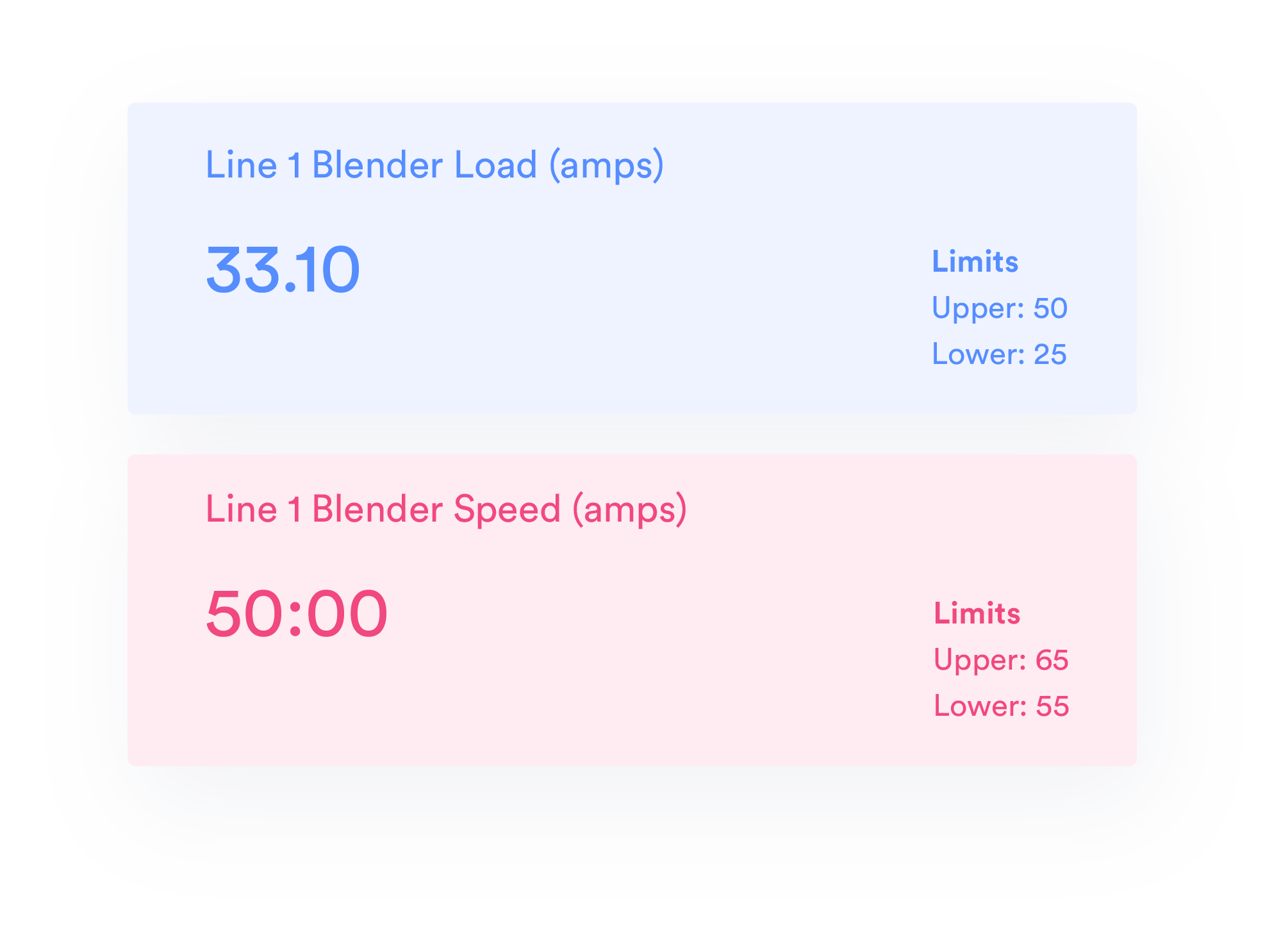

Equipment Performance

Connected to existing automation infrastructure, TrakSYS captures production counts, scrap counts, and current states of equipment to provide a clear view of what is happening on the plant floor and notifies of events requiring attention. Engage operators to detail specific root causes or corrective actions, to leverage their knowledge, for process improvement.

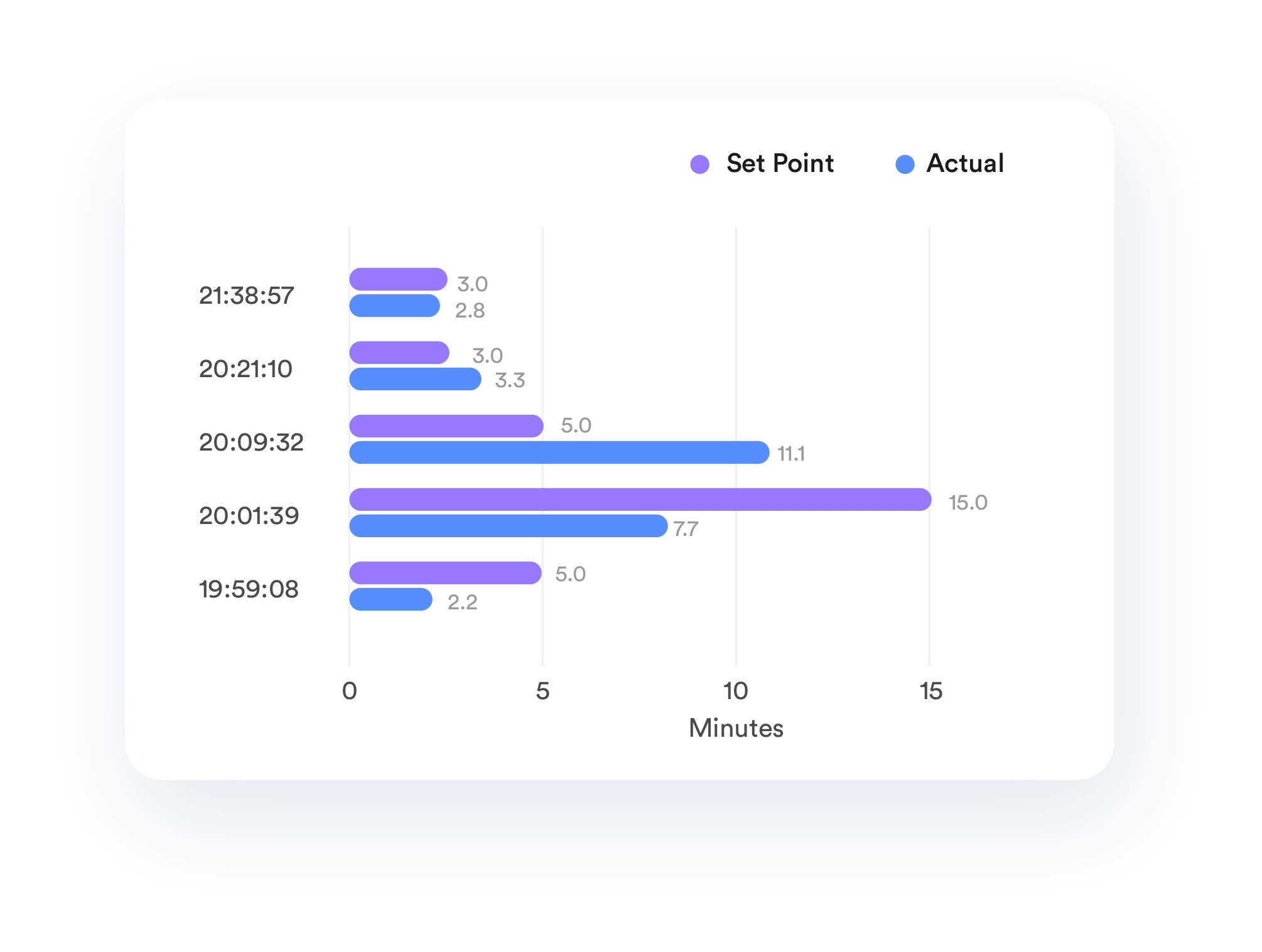

Changeover Performance

Efficient product changeovers are essential to minimizing excess inventory. TrakSYS communicates targets, procedures, and status for different changeover types. TrakSYS provides analysis of process performance for more accurate planning and scheduling as well as a roadmap for continuous improvement.

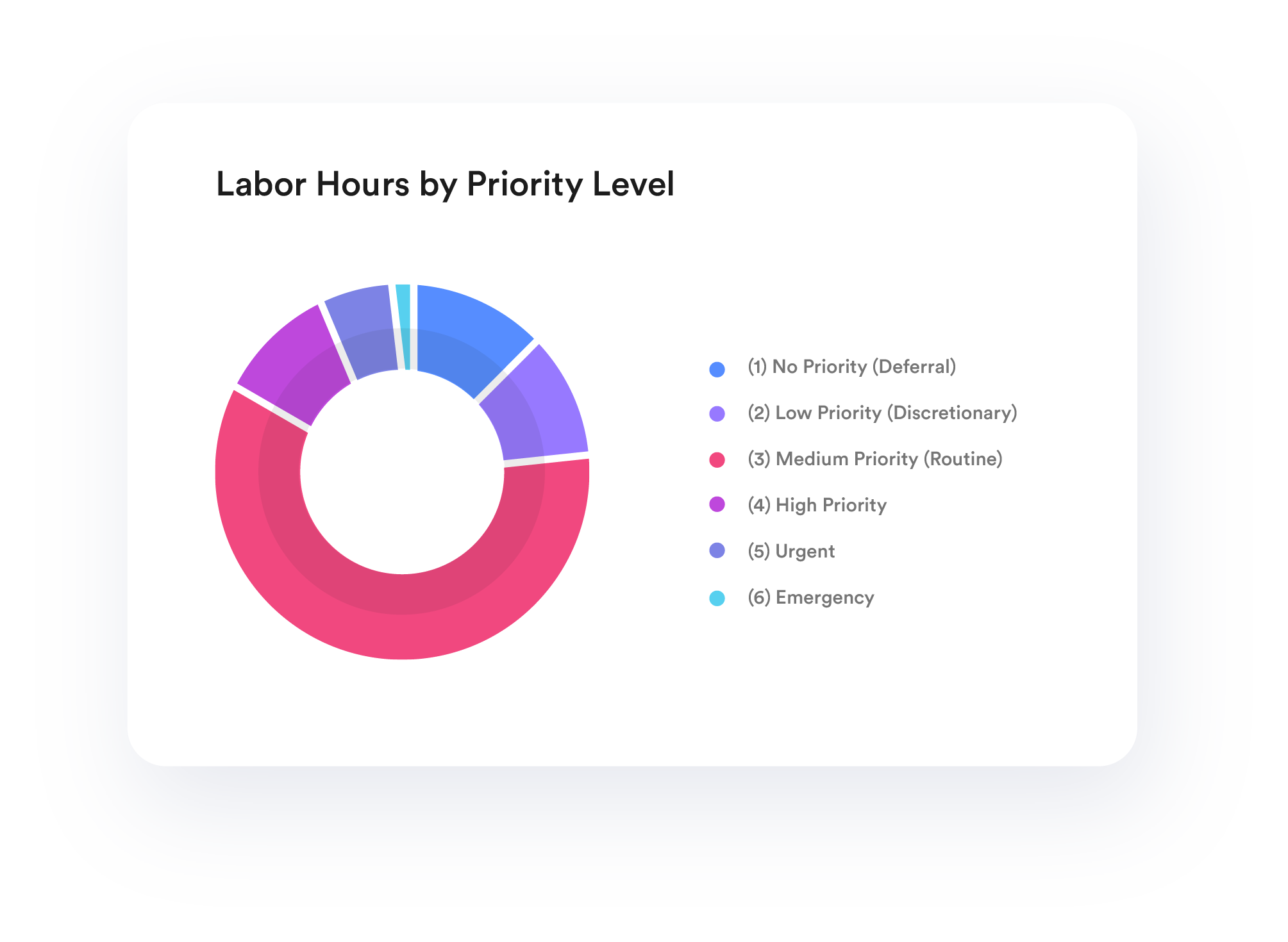

Maintenance Performance

Equipment uptime and performance is essential to plant productivity. TrakSYS provides solutions for efficiently managing work requests, track response times, wrench times, backlogs, on-time completion, and predict equipment failures. TrakSYS provides analysis of maintenance performance as a roadmap for continuous improvement as the factory evolves from reactive to proactive maintenance.

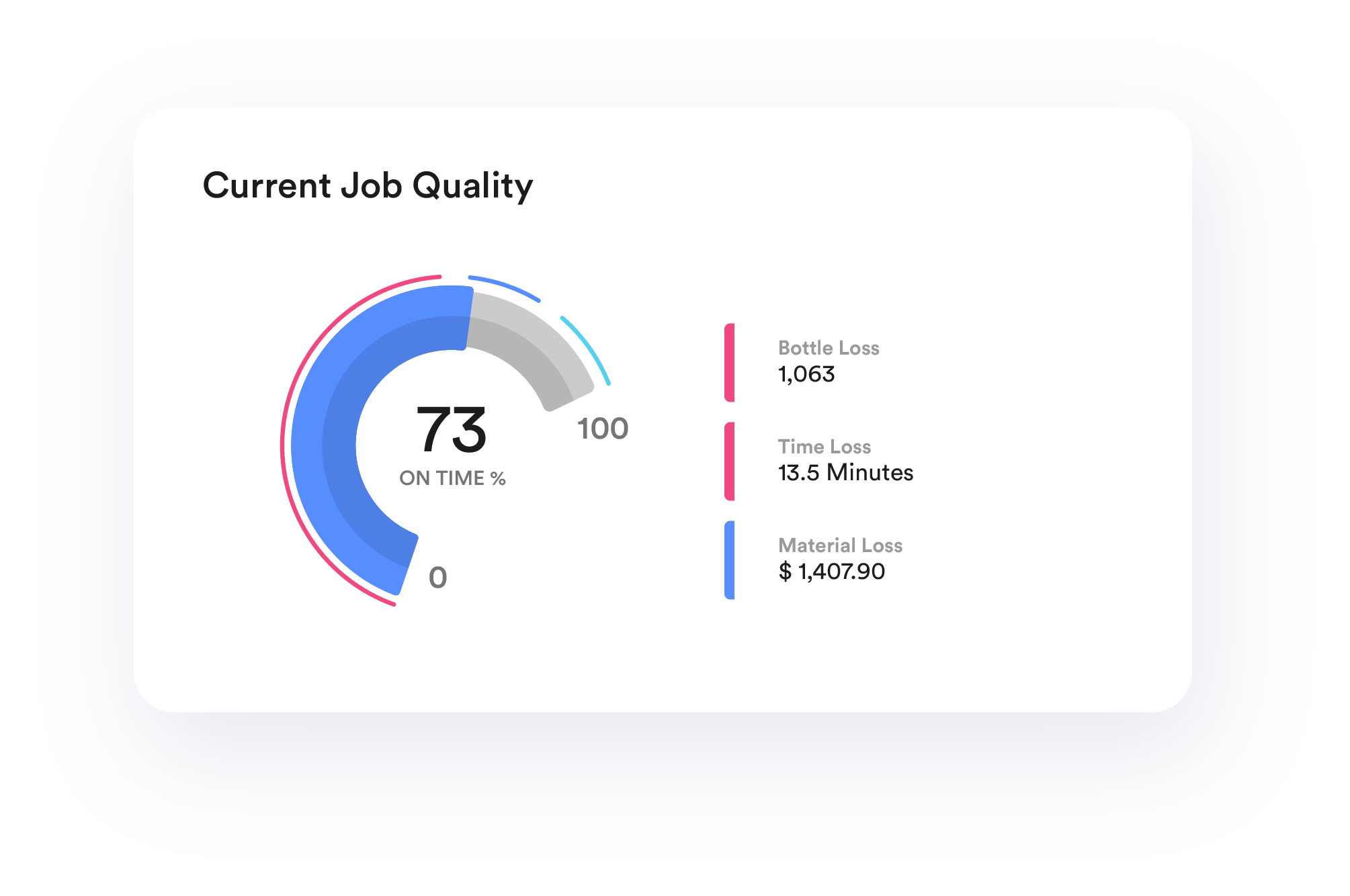

Quality Performance

Quality performance is essential to protecting brand recognition. TrakSYS provides solutions for efficiently tracking defects, errors, yield, and rework. TrakSYS provides analysis of quality performance as a roadmap for lowering costs of poor quality.

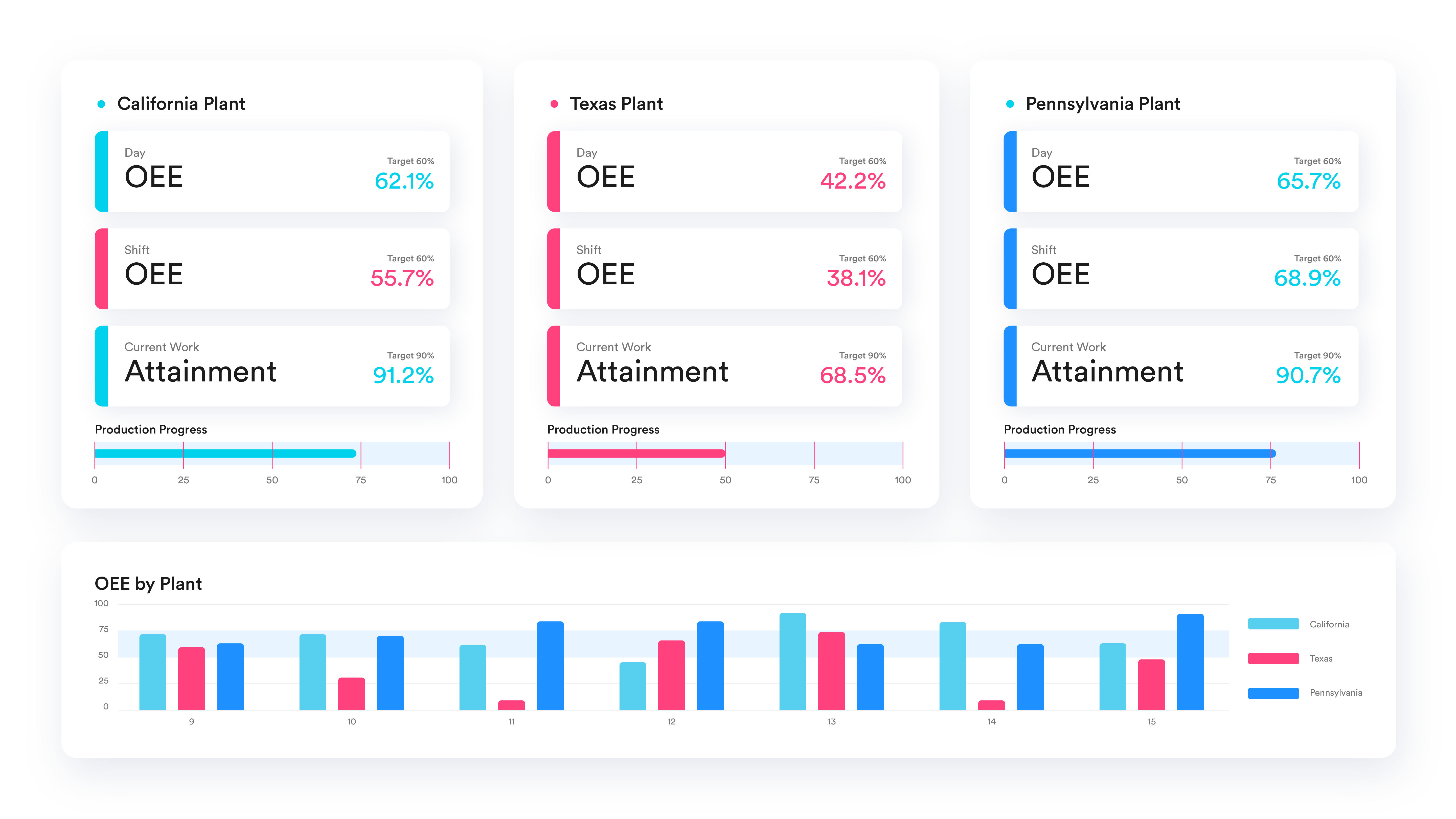

Enterprise Metrics & Reporting

Gain visibility into operation metrics and KPIs. In a multi-site deployment, TrakSYS provides analysis to compare the performance of lines and departments across plants to determine best practices across the enterprise. Quickly identify bottlenecks in the supply chain and prioritize improvement plans.

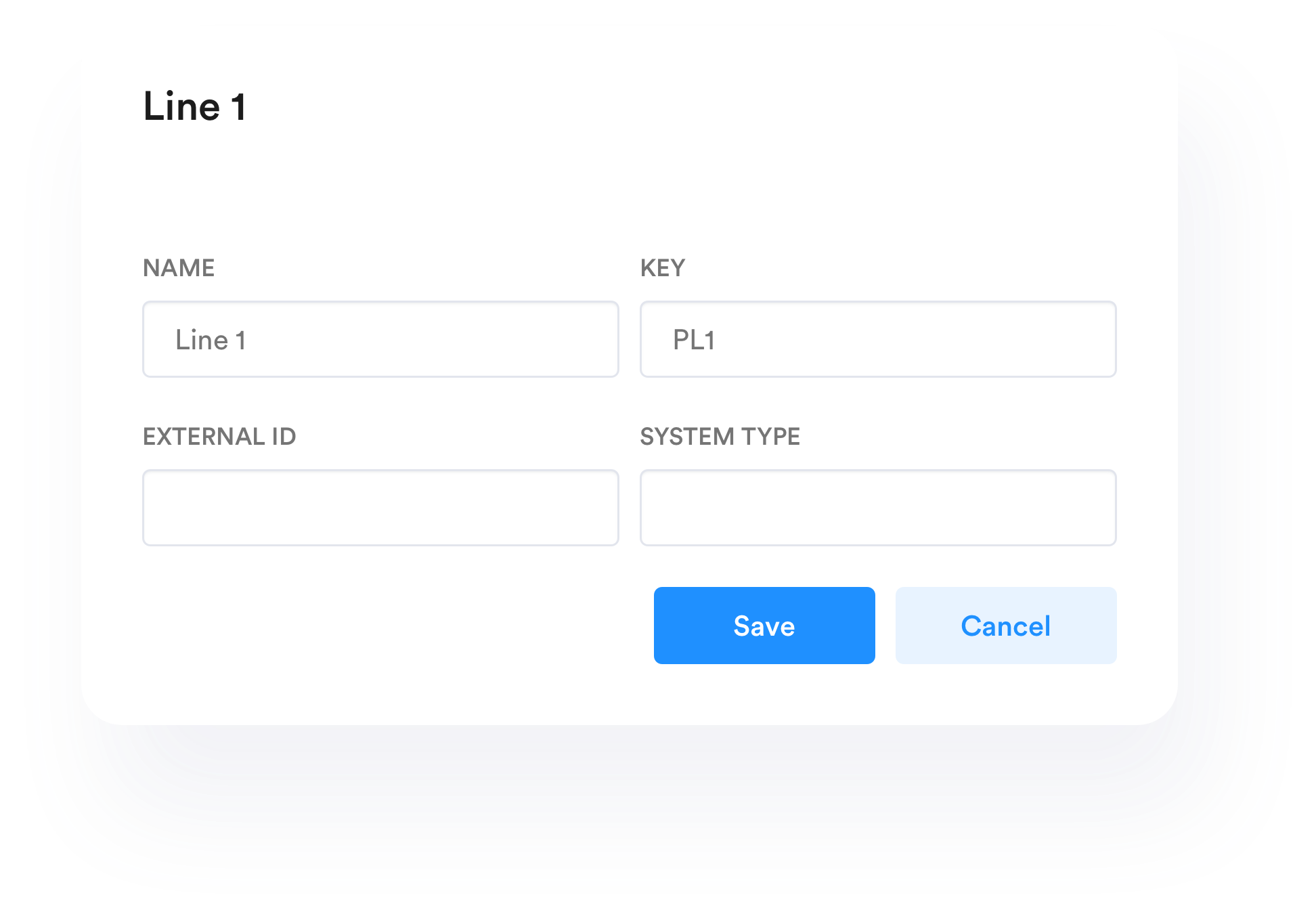

Configurability

Web-based configuration tools and an integrated scripting environment allow the construction of tailored maintenance management solutions without the need for custom code.

Extensibility

TrakSYS is a full manufacturing operations management (MOM) system, with standard function libraries that can be readily adjusted to create focused solutions in a fraction of the time compared to traditional development. This important functionality delivers both rapid deployment and cost-effective extensibility.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.