As we get closer to Q4 and the end of the year, we’re reaching a pivotal time for reflection and strategic planning. Year-end is a key inflection point; it calls for a thorough evaluation of performance, preparation for audits, reassessment of goals, and alignment on initiatives for the upcoming year.

Successful planning often hinges on the quality and accessibility of operational data needed to inform initiatives. This is where Manufacturing Execution Systems (MES) prove invaluable. While MES platforms are often associated with day-to-day production management, their role in strategic planning is just as meaningful. A robust MES like TrakSYS doesn’t just help streamline operations; it equips leadership with the real-time intelligence needed to make informed, high-impact decisions at year-end.

Table of Contents

Monitoring KPIs with MES

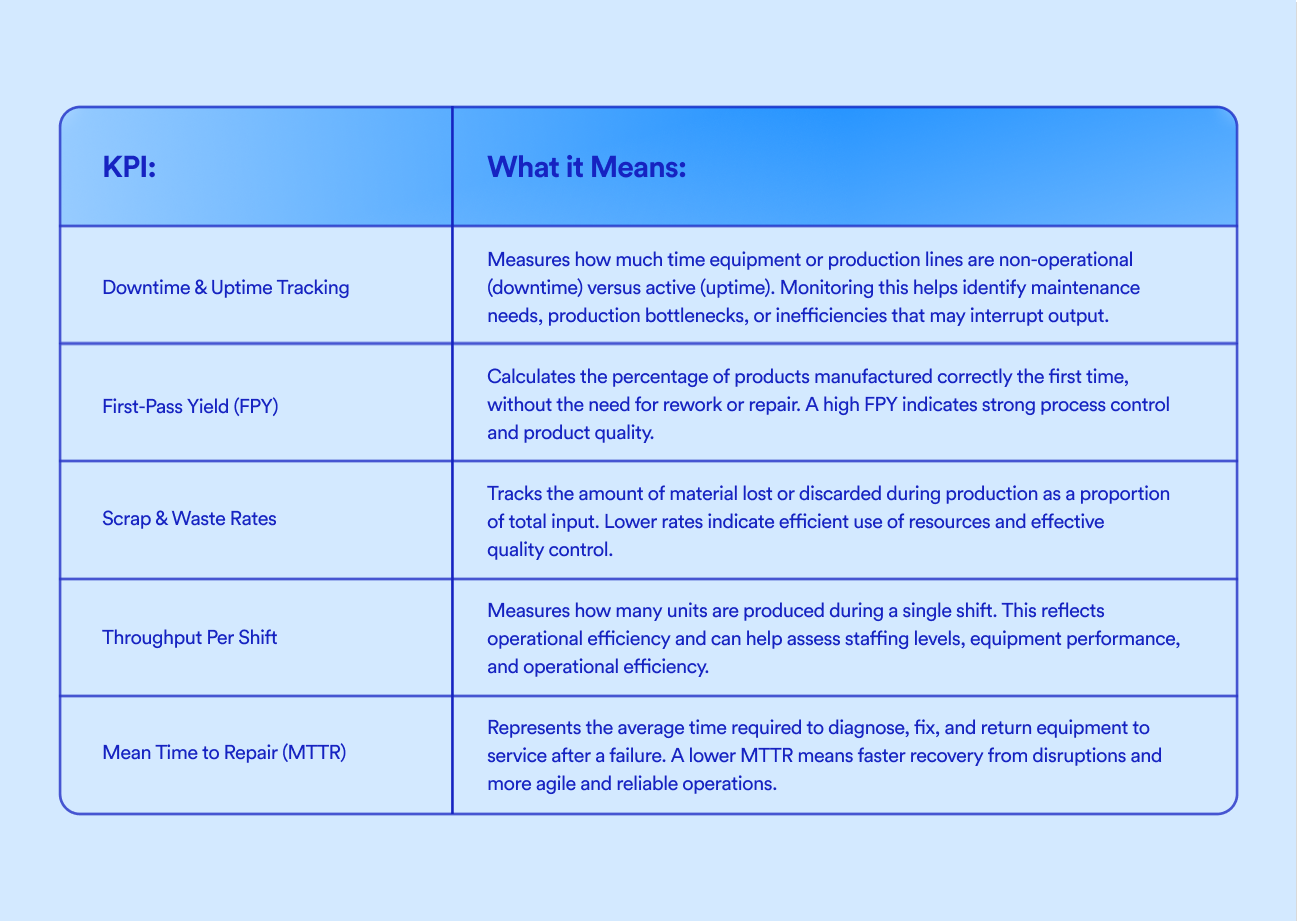

An effective MES continuously collects, organizes, and analyzes data from your factory floor. This abundance of contextualized information can be used to fuel Key Performance Indicators (KPIs) that are essential for evaluating the health, efficacy, and viability of your current operational strategies.

Within TrakSYS, real-time data becomes more than just numbers; it’s transformed into actionable insights. By integrating with things like PLCs, ERP systems, manual entries, and IIoT devices, the platform creates a seamless data pipeline, enabling accurate tracking of a wide range of KPIs. In a lean manufacturing environment, this transparency is vital for eliminating waste and driving continuous improvement.

Noteworthy KPIs

While OEE is a cornerstone metric, TrakSYS supports a range of KPIs that can offer insight into operations and identify areas for improvement. While far from an exhaustive list, here are some of the common KPIs businesses monitor with TrakSYS:

How KPIs Influence QBRs

At Parsec, we personalize each customer’s Quarterly Business Review (QBR). During these discussions, topics range from details on TrakSYS updates, customer readiness for pertinent technology such as AI, and the customer’s overarching goals for the coming fiscal year. We dive deep into what facets of production—and their overall supply chain—they have been monitoring, what has been going well, and where there may be opportunities for refinement and or expansion.

For context, when meeting with a customer who operates in the Food & Beverage industry, we may ask questions like:

- Are you tracking HACCP Compliance Rate? And how?

- What is your traceability time in the event of a recall or deviation in quality?

- Are you tracking Corrective and Preventive Action (CAPA) Closure Rates? And how?

Understanding—from the customer’s perspective—what has been working and where they would look to see improvement helps us deliver on our mission of being a value-additive technology partner.

TrakSYS in Action: Customer Case Study

The world leader in prepress solutions Agfa Graphics provides commercial, newspaper, and packaging services with an extensive range of integrated solutions.

With over 4,000 employees spread across 40 countries, Agfa Graphics needed an MES solution that would help optimize efficiency and integrate with complex workflows. Their choosen solution would need to help them access real-time data, enforce SMED and Lean manufacturing principles, eliminate the inaccuracies of manual data collection, and track stock levels—all to optimize productivity, profitability, and performance.

Through utilizing TrakSYS, the Agfa site in Suzano, Brazil, was able to:

- Reduce typical lead times by 24 hours

- Reduce scrap by 4%

- Reduce WIP by over 60% across two years

- Reduce Production startup times by 25%

Beyond these improvements, Agfa was able to empower its maintenance team with pertinent performance metrics, provide visibility into the root-causes of performance variation, and streamline its IT architecture.

Conclusion

Year-end planning isn’t just about looking back at what your organization achieved; it’s about moving forward with confidence. An MES can provide the data for both reflection and decision-making. By capturing real-time KPIs and transforming them into actionable insights, TrakSYS empowers manufacturers to navigate year-end with clarity. Whether you’re fine-tuning processes, setting new goals, or preparing for your next audit, TrakSYS is here to help.

Interested in discussing your year-end planning? Contact us today.